5V 10A Li-Ion Tester DT50W-20: Advanced Battery Cycler System for Professional Manufacturers

The 5V 10A Li-Ion Tester DT50W-20 by DK is engineered to meet the rigorous demands of professional manufacturers. This advanced battery cycler system is ideal for testing and analyzing Li-Ion batteries, providing precise data that aids in the development of high-performance battery packs. With its robust design and reliable performance, it stands as a vital tool in the battery manufacturing industry.

Why Choose the DK 5V 10A Li-Ion Tester?

Manufacturers looking for a dependable and efficient battery cycler system will find the DK 5V 10A Li-Ion Tester to be an indispensable asset. Its ability to deliver consistent results with high accuracy makes it perfect for extensive battery testing and quality control. The system’s user-friendly interface and flexible testing parameters allow for customized test cycles, ensuring comprehensive analysis for every battery type.

Key Features and Benefits

- High Precision Testing: Achieve accurate and reliable results with advanced technology designed for professional-grade battery testing.

- Robust Design: Durable construction ensures long-term use, making it a cost-effective solution for manufacturers.

- Flexible Testing Options: Customize test cycles to meet specific requirements, providing versatility in battery analysis.

- Comprehensive Data Analysis: Obtain detailed insights into battery performance, aiding in the development of superior battery products.

Applications of the 5V 10A Li-Ion Tester

This battery cycler system is ideal for a wide range of applications, including:

- Battery manufacturing and R&D

- Quality control in battery production

- Performance testing of Li-Ion battery packs

Invest in the Best with DK

Choose the DK 5V 10A Li-Ion Tester DT50W-20 for your manufacturing needs and ensure your batteries meet the highest standards of quality and performance. Contact us today to learn more about how this advanced system can elevate your battery testing processes.

Lithium Battery Charge Discharge Testing and Balance Maintenance Machine DT50W-20

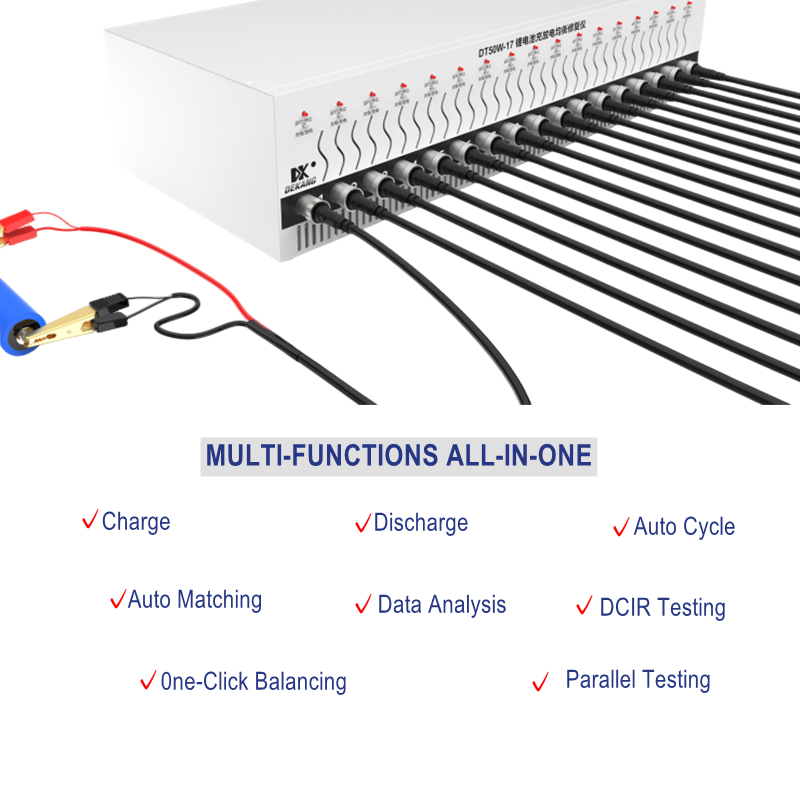

is capable of conducting capacity tests, charge and discharge characteristic tests, capacity grading and matching, balance maintenance, internal resistance tests, data analysis & comparison, etc., for a variety of Lithium batteries, NiMH batteries, and NiCD batteries. It offers physical compatibility with 18650, 26650, 32650, 33140 cells as well as pouch and prismatic cells. With its isolation measurement design, the DT50W can balance charge & discharge individual cells within a battery pack to ensure uniformity while identifying any faulty cells without requiring disassembly and restore unbalanced battery packs to their normal balanced state through balancing charge-discharge operations.

The device features a modular design, enabling parallel testing with a maximum current capacity of 200A.

The device is widely utilized in battery production facilities, battery recycling plants, research laboratories focusing on batteries development or new energy vehicle batteries testing and maintenance.

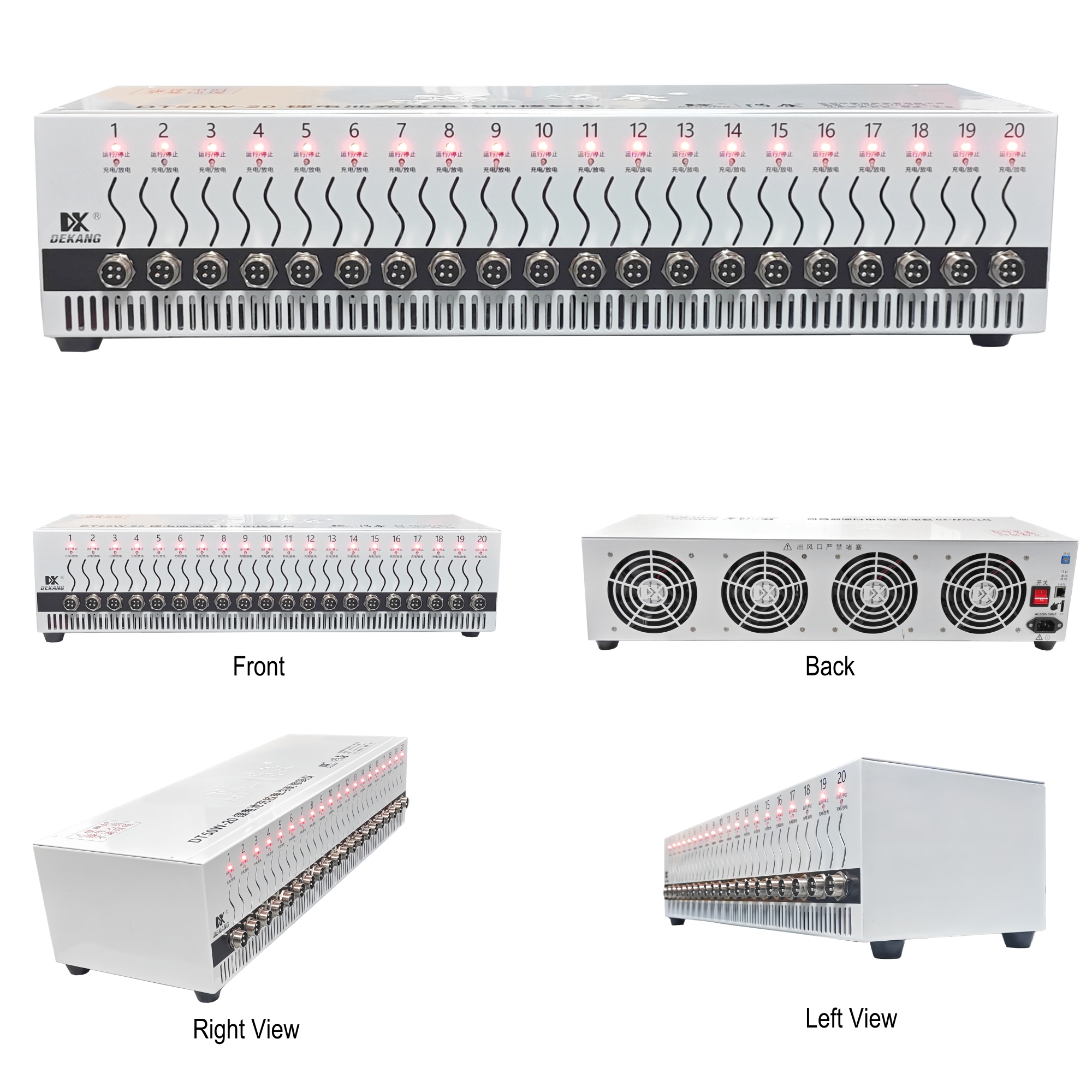

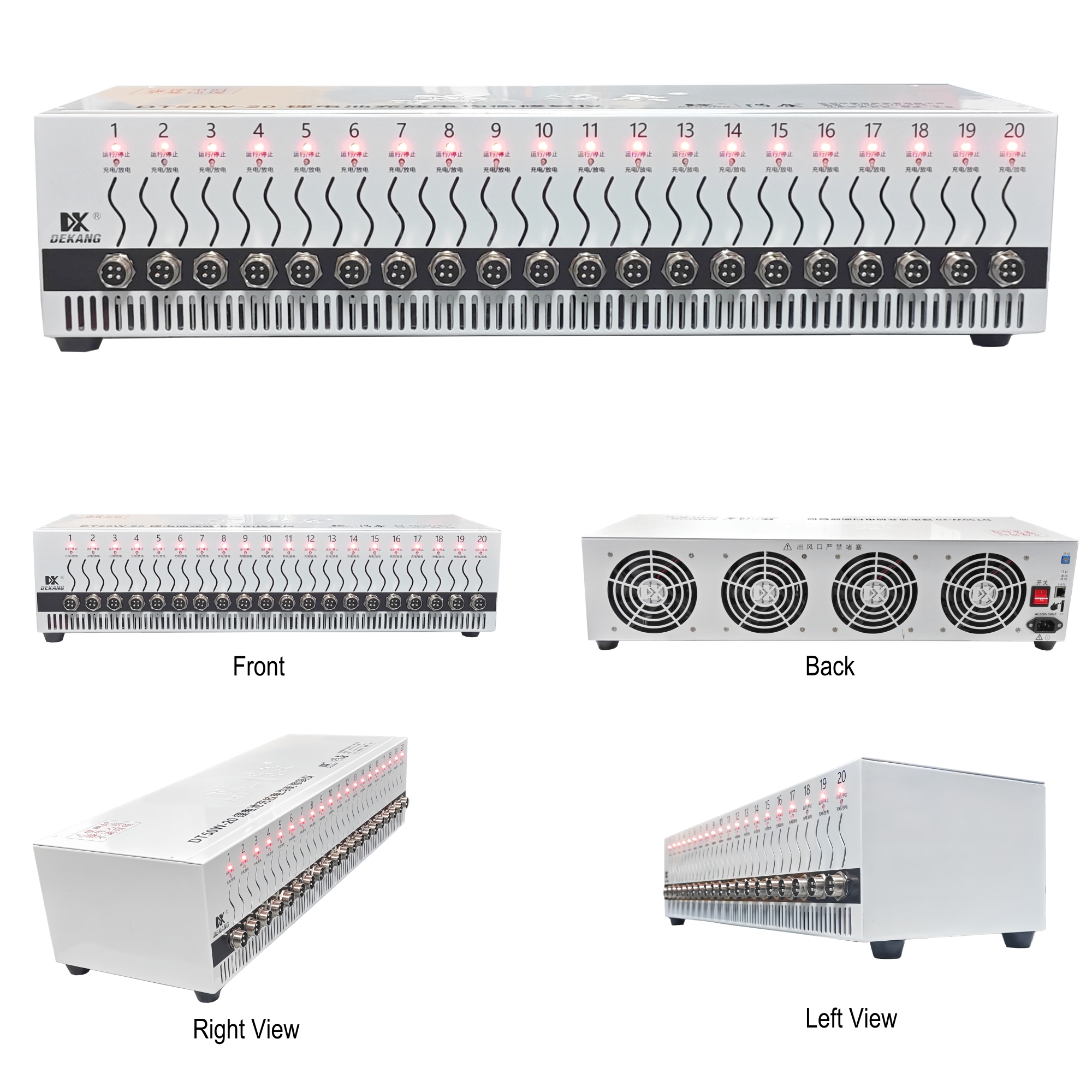

Product Display

Lithium Cell Charge Discharge Testing and Balance Maintenance Machine

Model No.: DT50W-20

Max. Single Channel Output: 5V 10A

Max. Parallel Output: 5V 200A

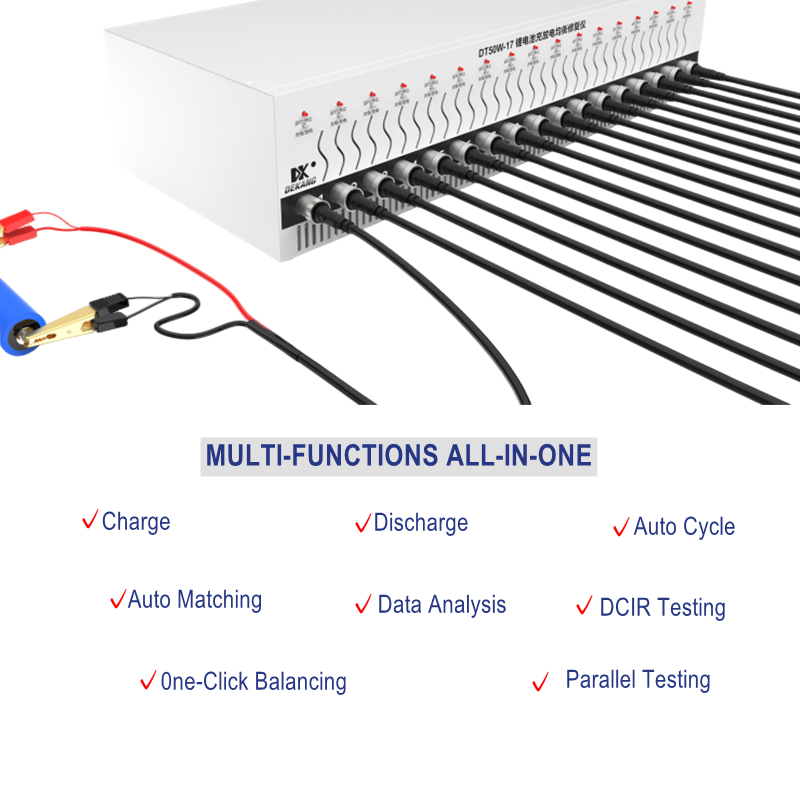

Intelligent, multi-functional, one machine to meet different testing needs

Modular Design, Easy Maintenance

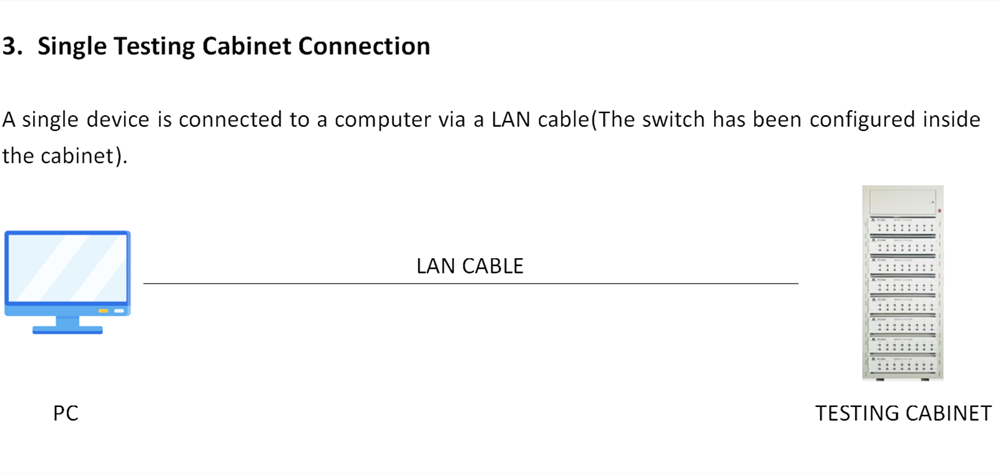

The modular design enables flexible combinations, allowing multiple devices to be integrated into a testing cabinet for efficient and rapid completion of testing and maintenance tasks for the entire battery pack.

Isolated channel design, each channel is independently controlled and does not affect each other. After-sales maintenance is simple and convenient. If a single channel fails, just replace the module to complete the repair.

DT50W-160 is composed of the single DT50W-20, a number of DT50W-160 can constitute a testing group to match the needs of mass testing.

Lithium Cell Capacity Grading and matching Test System

DT50W-160

Applicable Batteries:

Battery cells of Li-Ion, polymer, Ni-MH, Ni-Cd, etc.

Features:

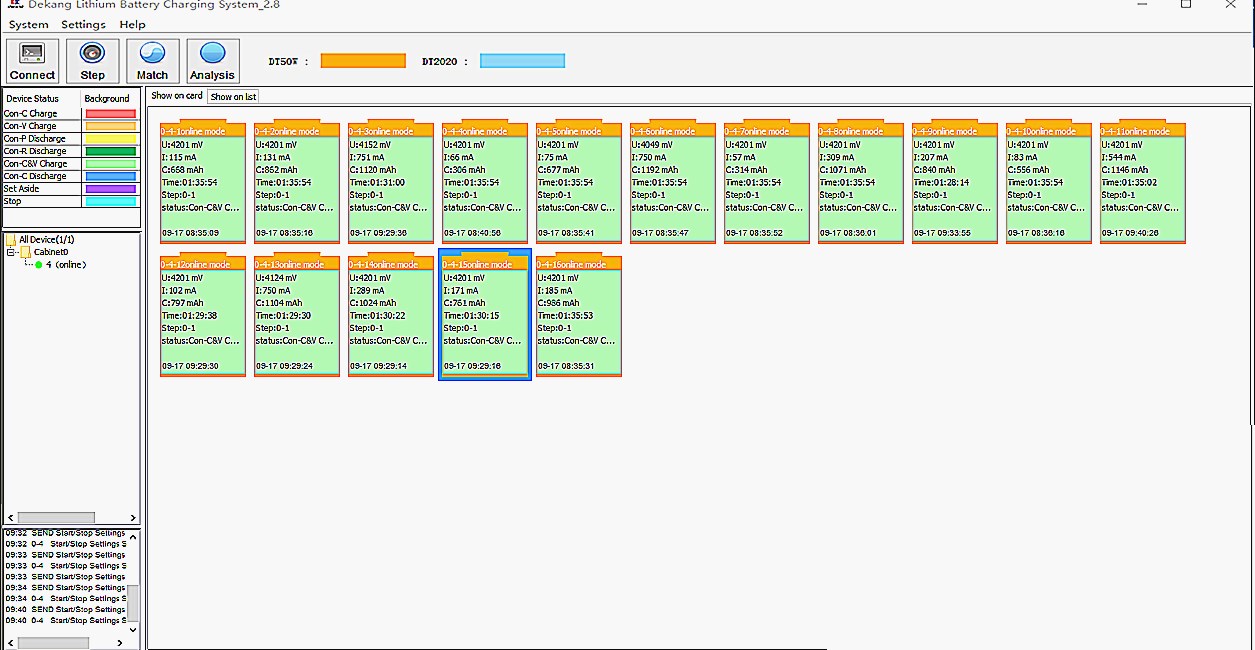

• Each channel is equipped with a dedicated processor to ensure a perfect level of capacity calculation, timing, voltage and current control.

• Fully isolated design, each channel is equipped with an independent processor, it can directly test the cells of the battery pack.

• Independent heat source channel, temperature control and speed regulation fan.

• The LED light indicates the running status, testing status, matching status, and alarm status.

• Fully compatible with the batteries of Li-ion, Polymer, Ni-MH, NiCd, and so on.

• Fully compatible installation with 18650, 26650, 32650, pouch, prismatic batteries.

• The height of the probe is adjustable, ruler scale for easy leveling

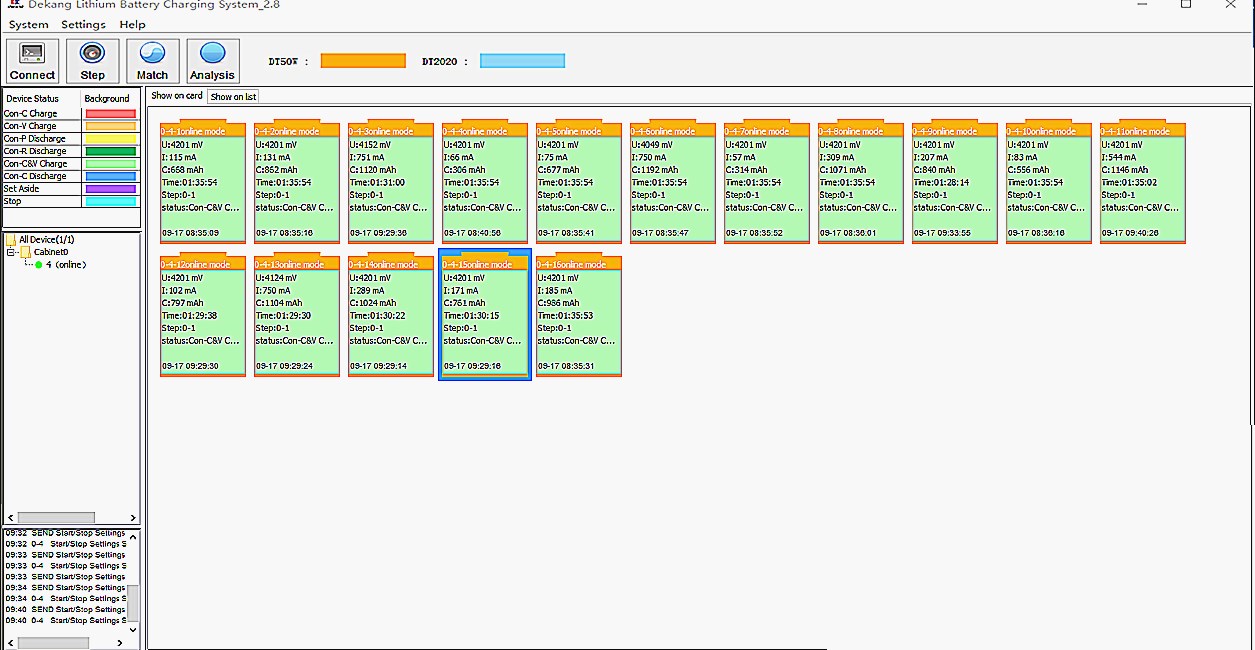

• Online test between computer and device, the setting and result is particular and plentiful,

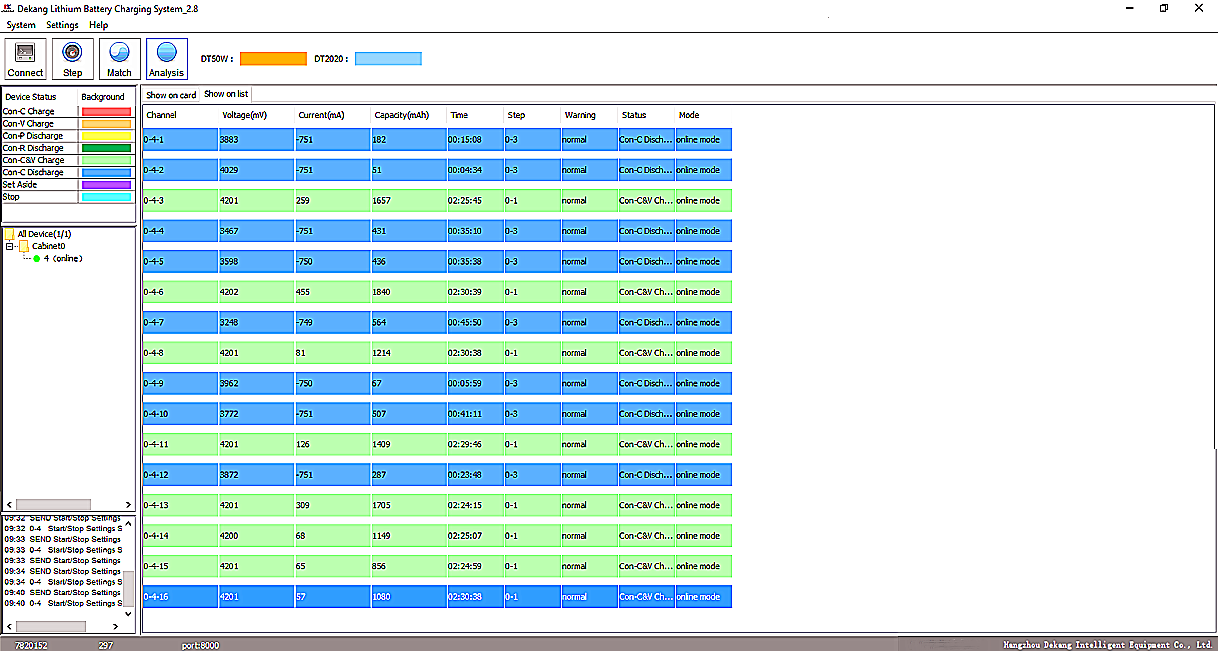

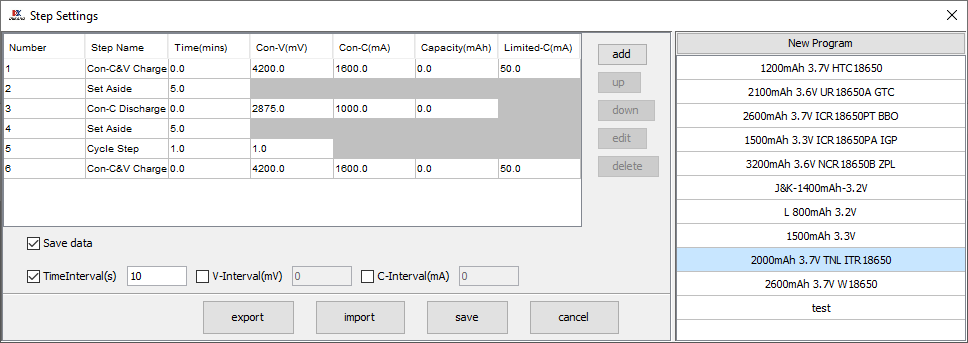

• With the work steps of Constant Current Discharge, Constant Power Discharge, Constant Resistance Discharge, Constant Current Charge, Constant Voltage Charge, Constant Current & Voltage Charge, Internal Resistance Test and Idle, etc.

• Work step automatically switching.

• The charge and discharge parameters can be customized.

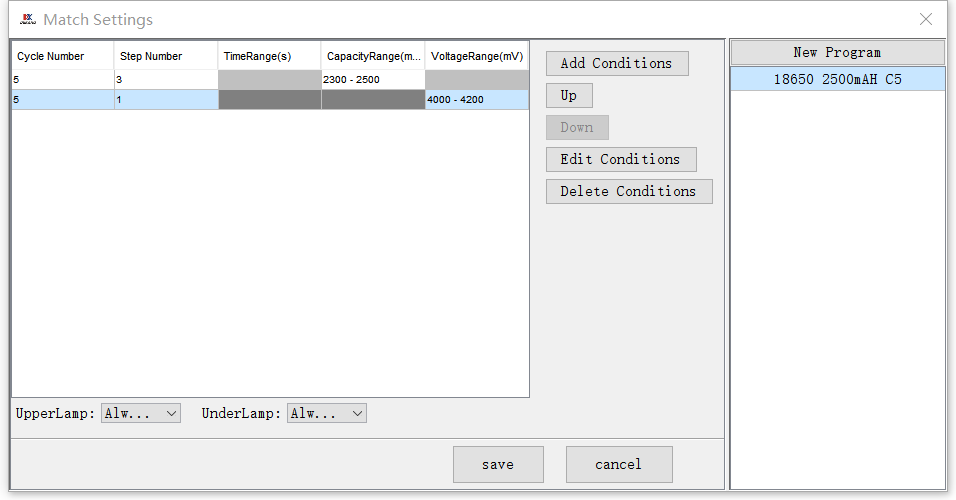

• The powerful data matching function automatically identifies channels that meet or do not meet the matching standards. It also indicates the corresponding channels by flashing the indicator light, making battery grading more convenient.

• With channel parallel testing function, the maximum parallel current output 200A.

• One click balance recondition battery pack voltage difference, making battery repair simple and easy.

• Battery anti-reverse connection protection and alarm.

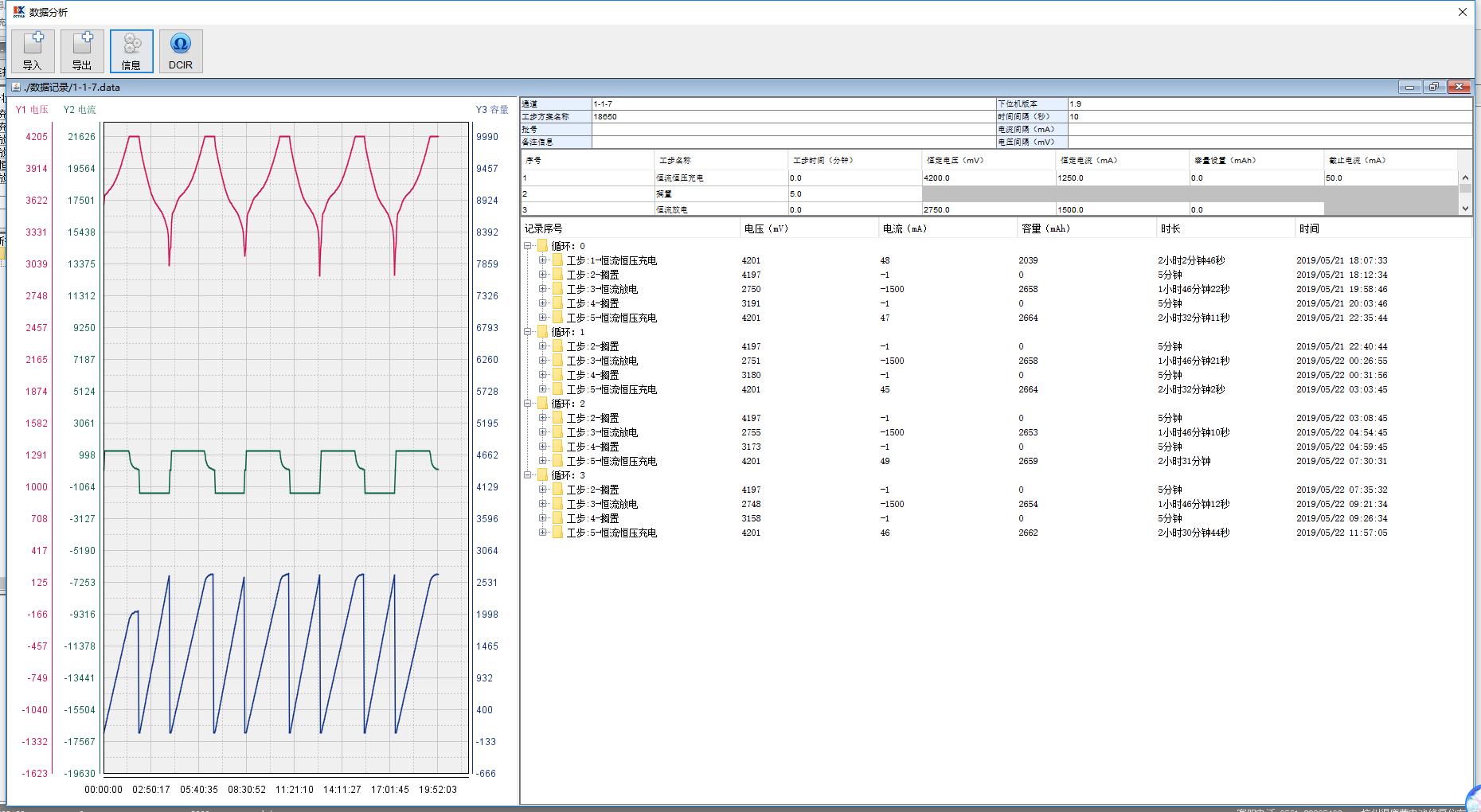

• The recording function of the test process

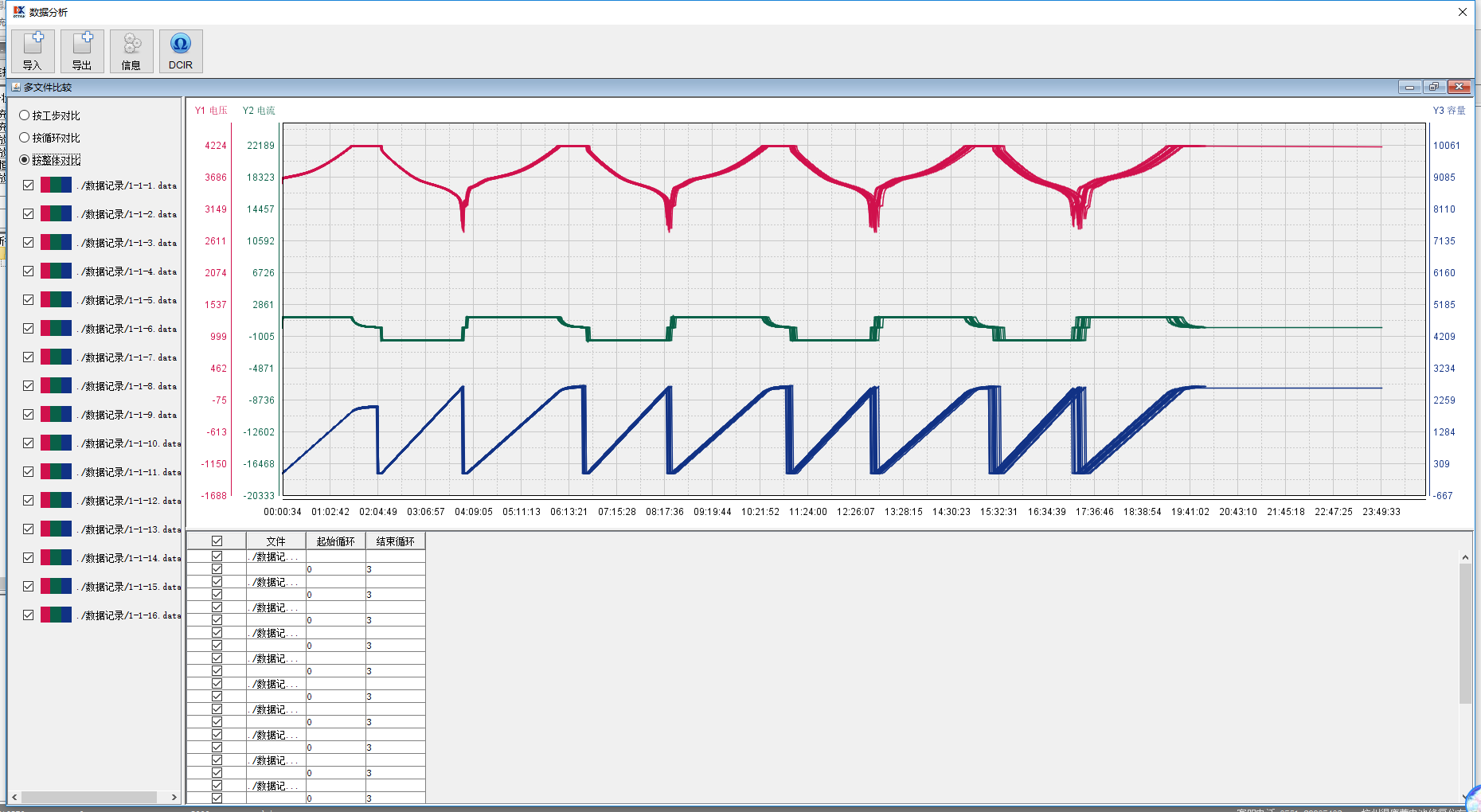

• With 3 Y-axis (voltage, current, capacity) and a time axis curve drawing ability, and data report function.

• The color of the test status bar is customized, which makes it easy to check the test status of all devices when the number of tests is large.

Technical Specification:

|

Model No.: DT50W-20

|

|

Input Voltage:

|

AC 220V± 10% 50Hz/60Hz

|

|

Input Power:

|

No-load 80W, full load 1650W

|

| Number of Channels |

20 |

| Channel Control Mode |

Independent control |

| Single Channel Parameter |

|

Voltage

|

Max. Charge Constant Voltage:

|

5V

|

|

Min. Discharge Cut-off Voltage:

|

1V

|

|

Tolerance:

|

0.02V

|

|

Current

|

Max. Charge Current:

|

10A

|

|

Max. Discharge Current:

|

10A

|

|

Min. Charge Cut-off Current

|

0.05A

|

|

Tolerance:

|

0.02A

|

|

Power

|

Max. Output Power ( Single Channel )

|

100W

|

|

Data Recording

|

Data Recording Conditions

|

Time interval

|

|

Voltage interval

|

|

Current interval

|

|

Charge

|

Charge Modes:

|

Constant current charge

|

|

Constant voltage charge

|

|

Constant current & voltage charge

|

|

Charge Cut-off Conditions:

|

Voltage, Current, Time, Capacity, -△V

|

|

Discharge

|

Discharge Modes:

|

Constant current discharge

|

|

Constant power discharge

|

|

Constant resistance discharge

|

|

Charge Cut-off Conditions:

|

Voltage, Current, Time, Capacity

|

|

Cycle

|

Cycle Index:

|

1-500 times

|

|

Cycle Nest

|

Nestable

|

|

Protection

|

Power-down protection

|

|

Reverse connection

|

|

Over-temperature protection

|

|

Over-voltage protection

|

|

Short-circuit protection

|

| |

| Extended Function |

Parallel Channel Testing |

Maximum parallel current output: 200A |

| One-Click Balancing Function |

Maximum balance current output: 10A |

|

IP Grade

|

IP20

|

|

High Voltage Insulation Between Channels

|

AC1000V/2min Normal

|

|

Voltage & Current Test Sampling

|

Five-core wires connection / Probe

|

|

Noise

|

< 76 dB

|

|

Host Computer Communication Method

|

based on TCP/IP protocol

|

|

Test Report Output Method

|

Excel

|

|

Server Disk Configuration

|

>100GB

|

| Server Operating System |

WINDOWS XP or above system with LAN port configuration |

|

Communication Port

|

LAN

|

|

Equipment Work Ambient Conditions

|

|

Operation Ambient Temperature

|

0 ℃ - 40 ℃

|

|

Storage Temperature

|

-10 ℃ - 50 ℃

|

|

Operation Ambient Humidity

|

≤ 70 % RH (No condensation)

|

|

Storage Ambient Humidity

|

≤ 80 % RH (No condensation)

|

Illustrations:

Optional Battery Connection Fixtures

(Remarks: Customized options such as row connectors and BMS adapter plates are available)

Connection Schematic Diagram of Battery Pack Balance Maintenance

Default Standard Accessories

1. Testing cables with alligator clips----------------20 pcs

2. Power cord--------------------------------------------- 1 pc

3. LAN cable-----------------------------------------------1 pc

(Remarks: Additional battery connection fixtures need to purchased separately. Additionally, customized options such as row connectors and BMS adapter plates are available)

Packing Information

Product Size: 66*26*16 cm(L*W*H)

Pcs/Ctn: 1 pc/ctn

Package Size: 78*41*29 cm(L*W*H)

G.W.: 19.50 kgs

N.W.: 17.50 kgs

Software Interfaces

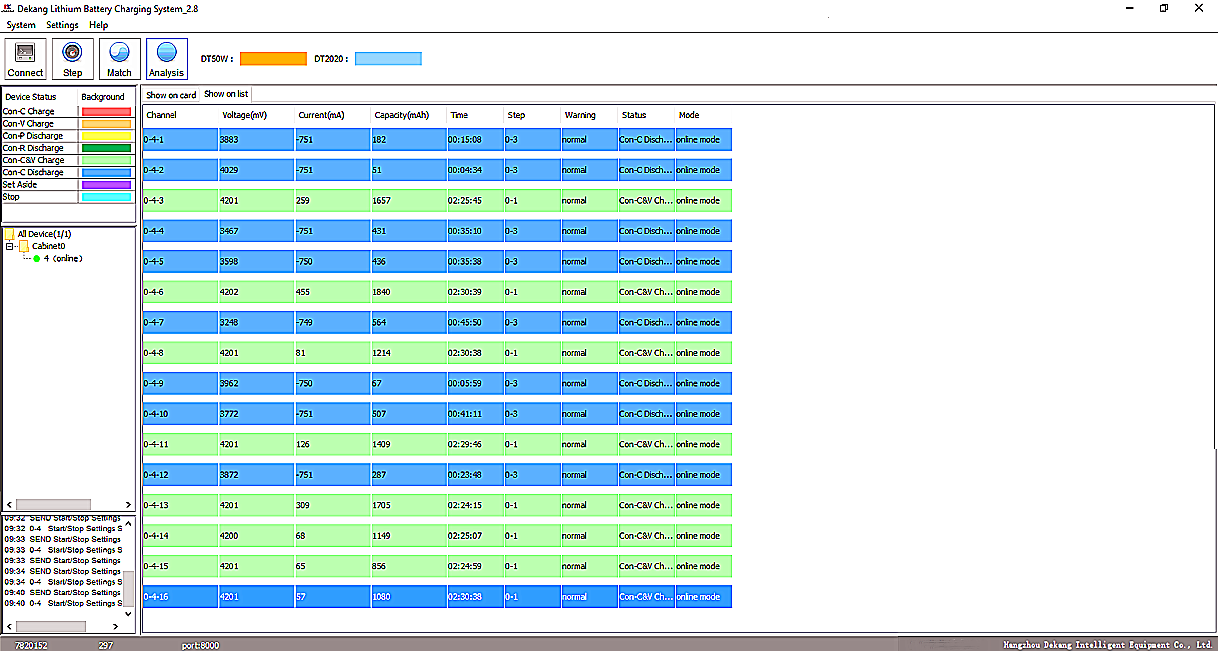

Main Interfaces

List Display

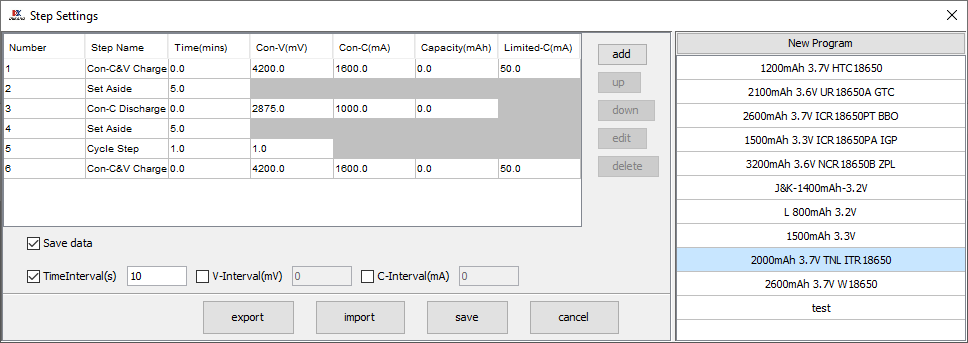

Work Step Setting

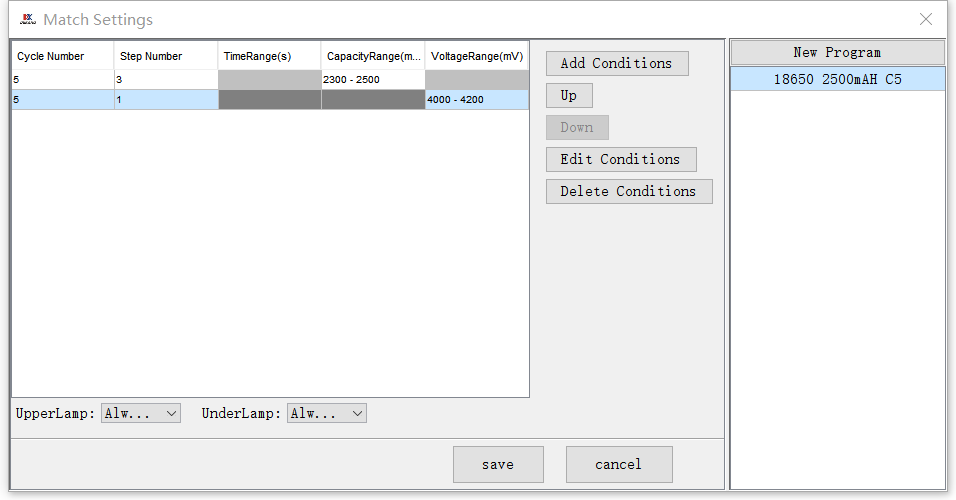

Match Conditions Setting

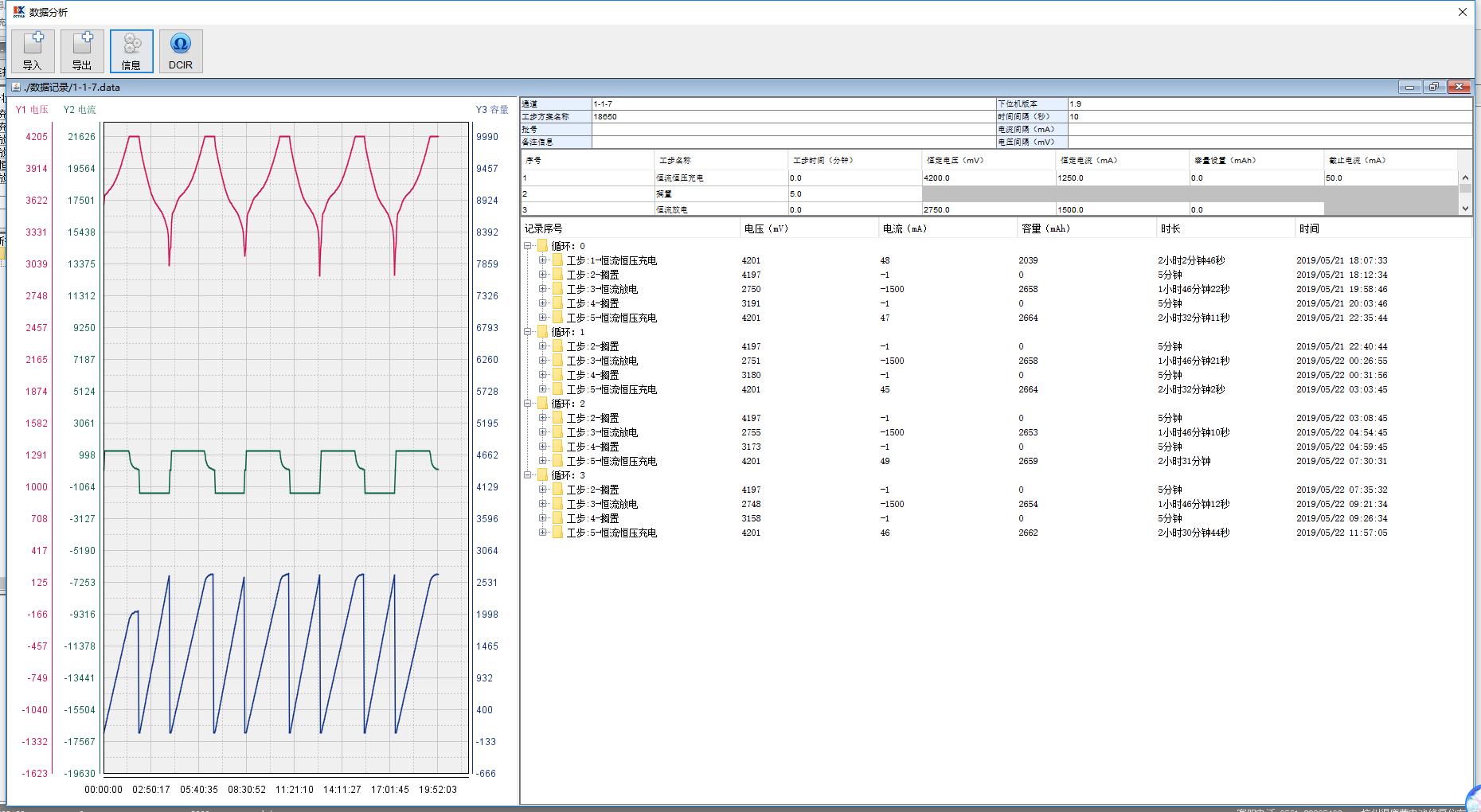

Single Channel Data Analysis

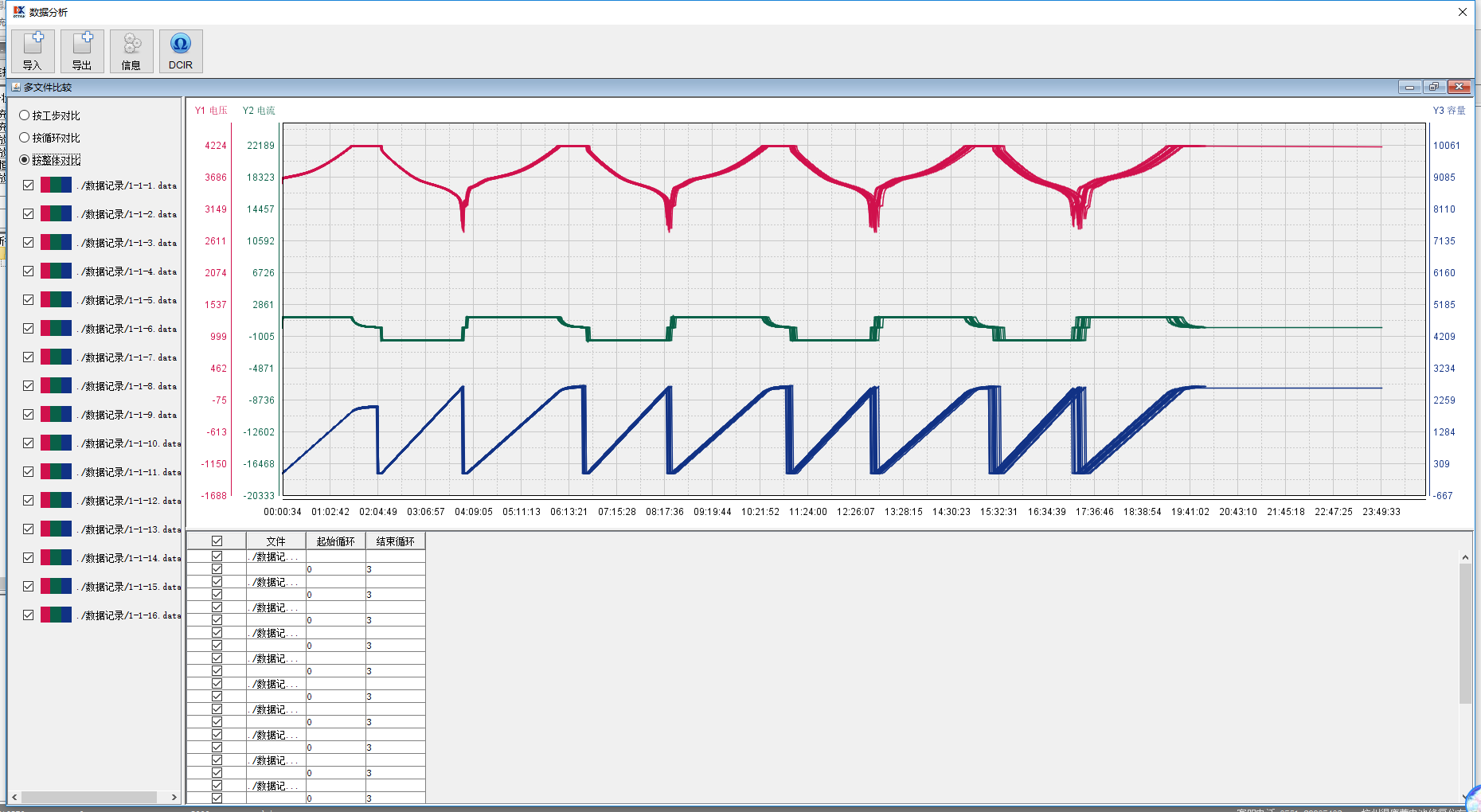

Multiple Channel Data Analysis and Comparison

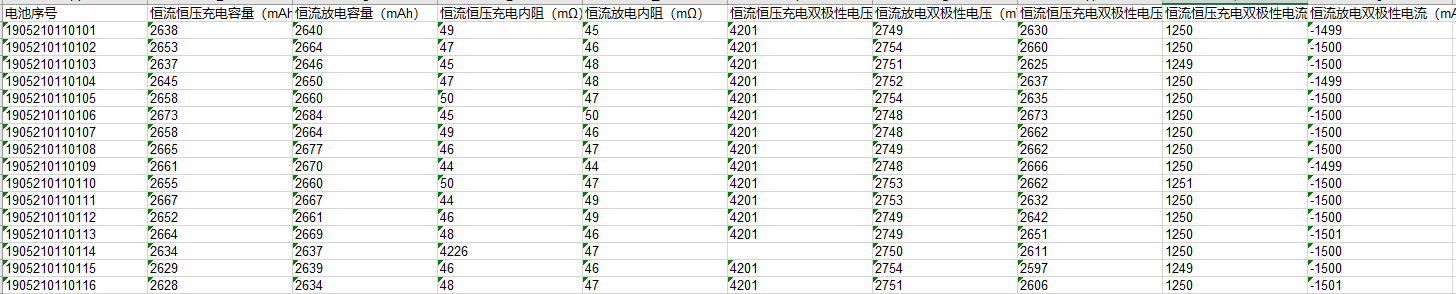

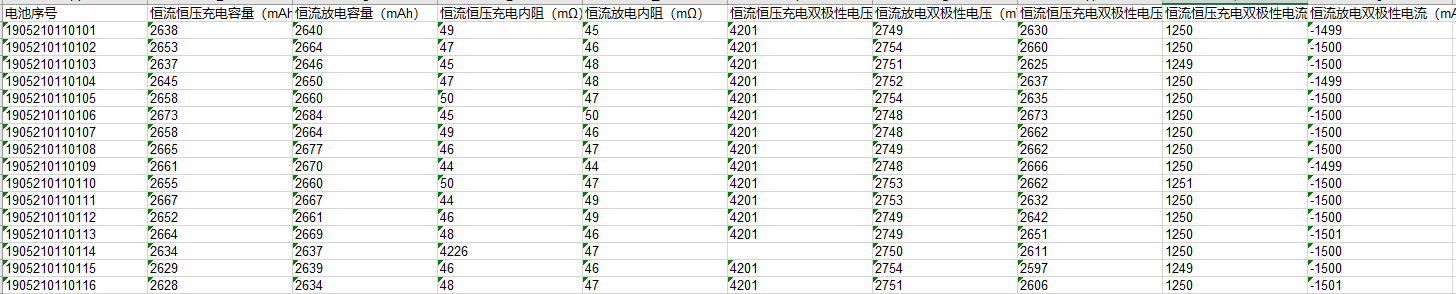

Test Data Exporting

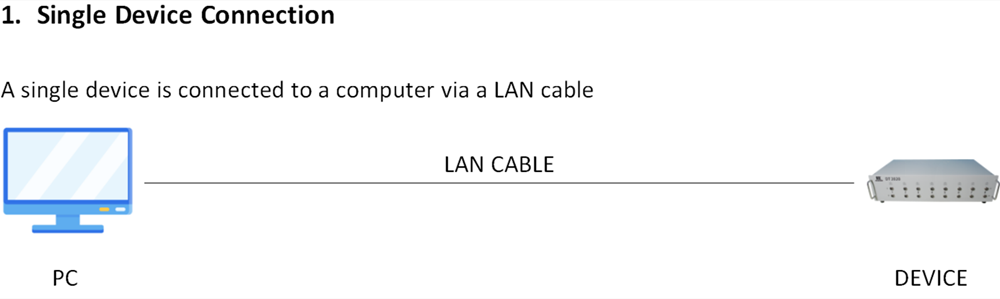

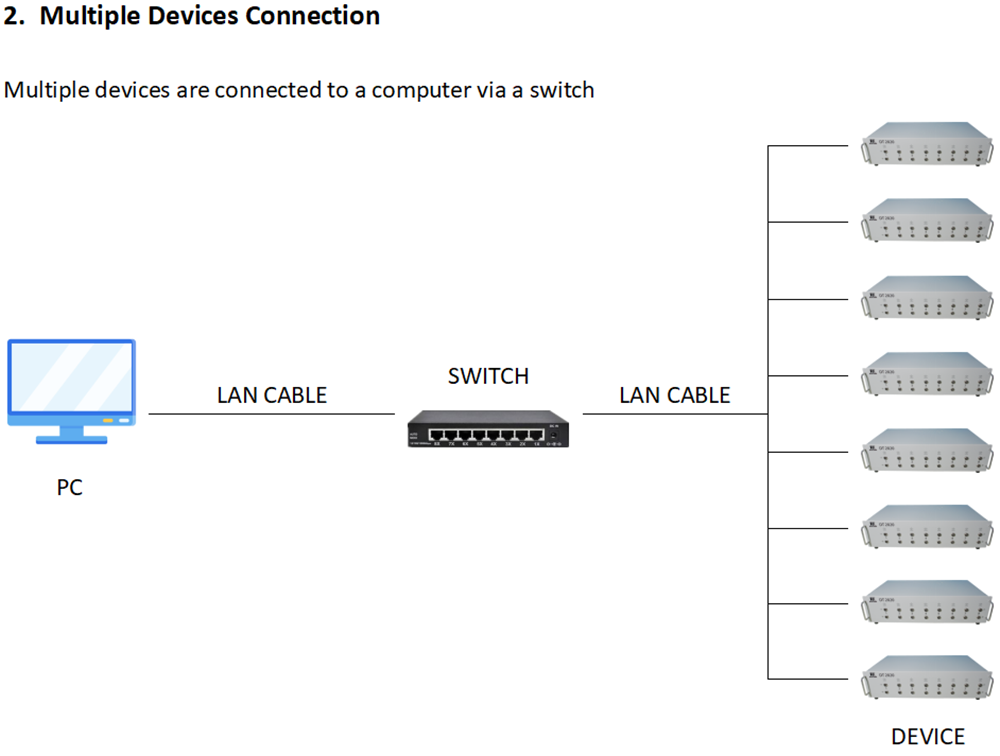

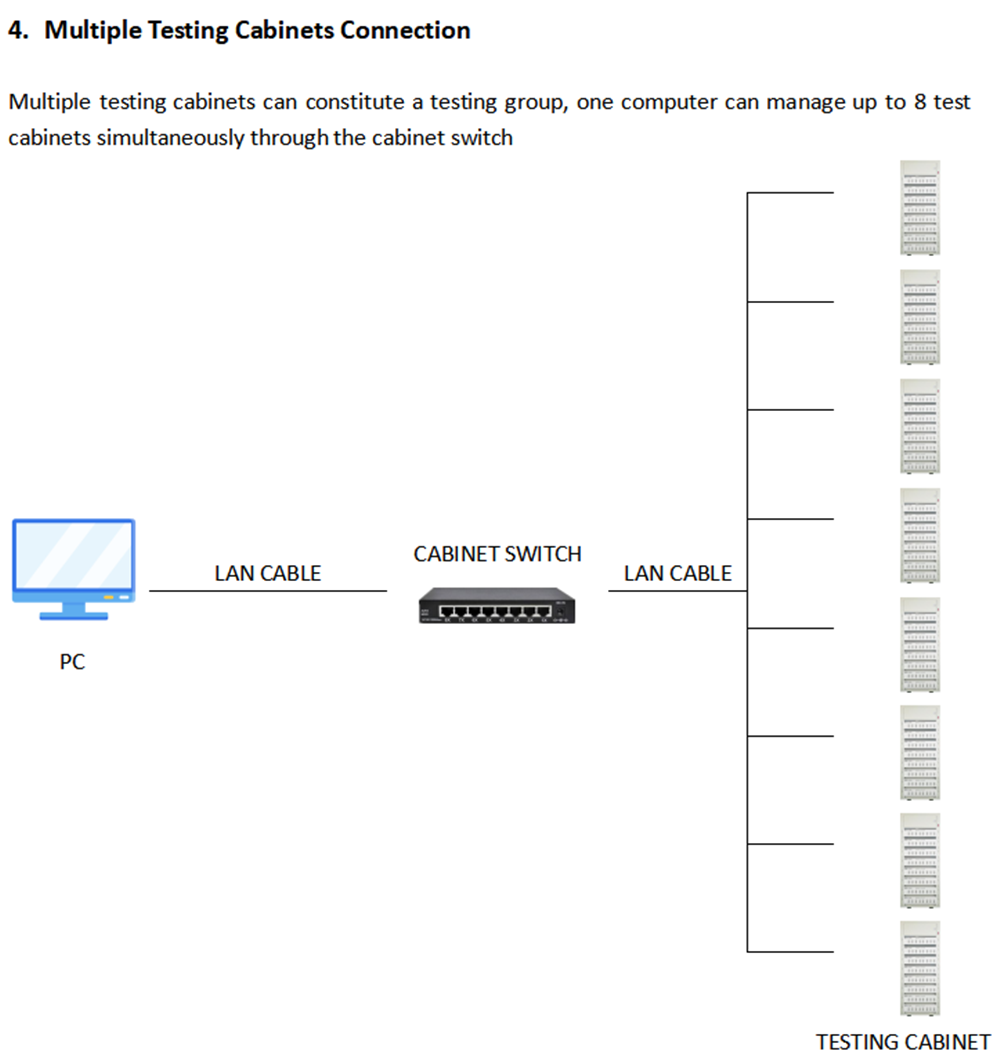

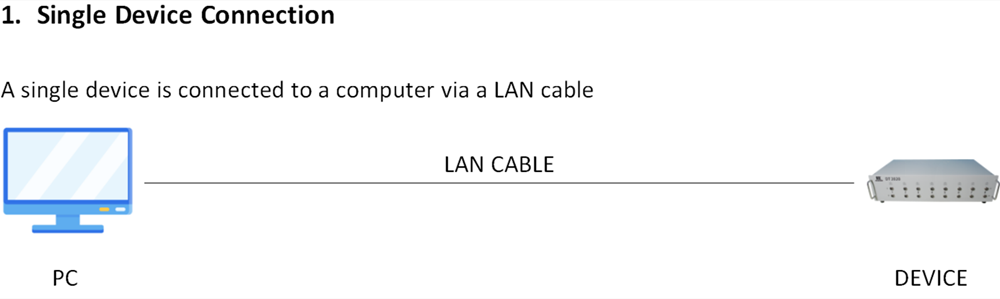

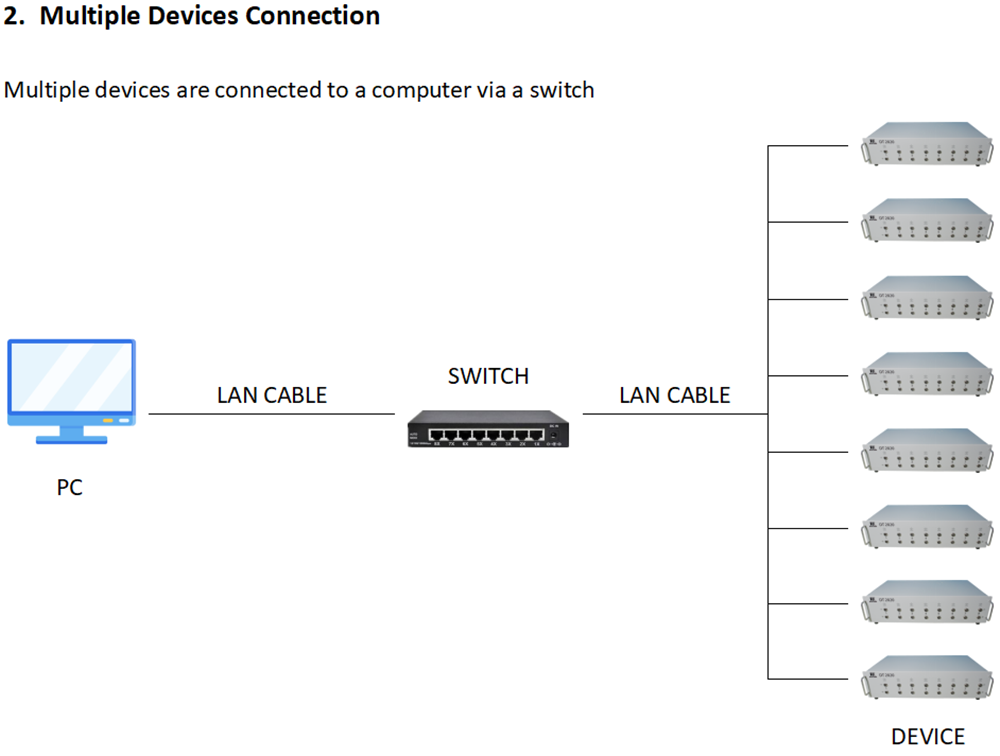

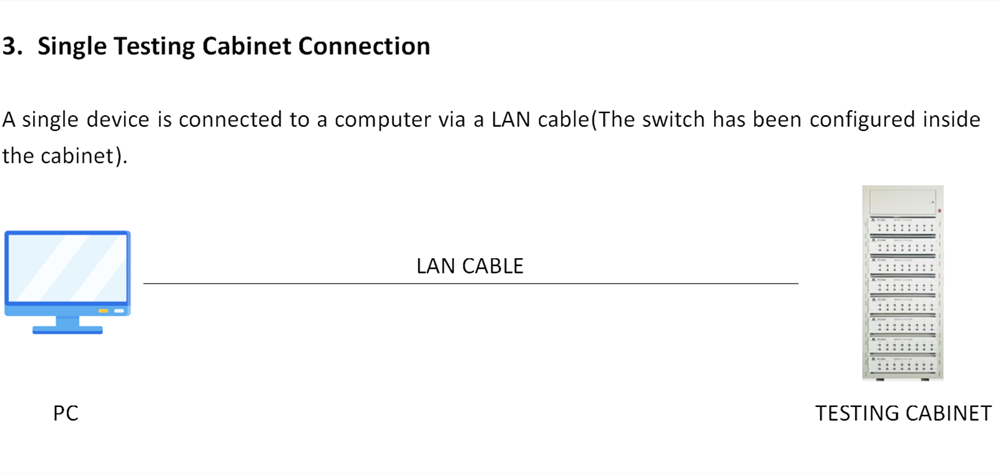

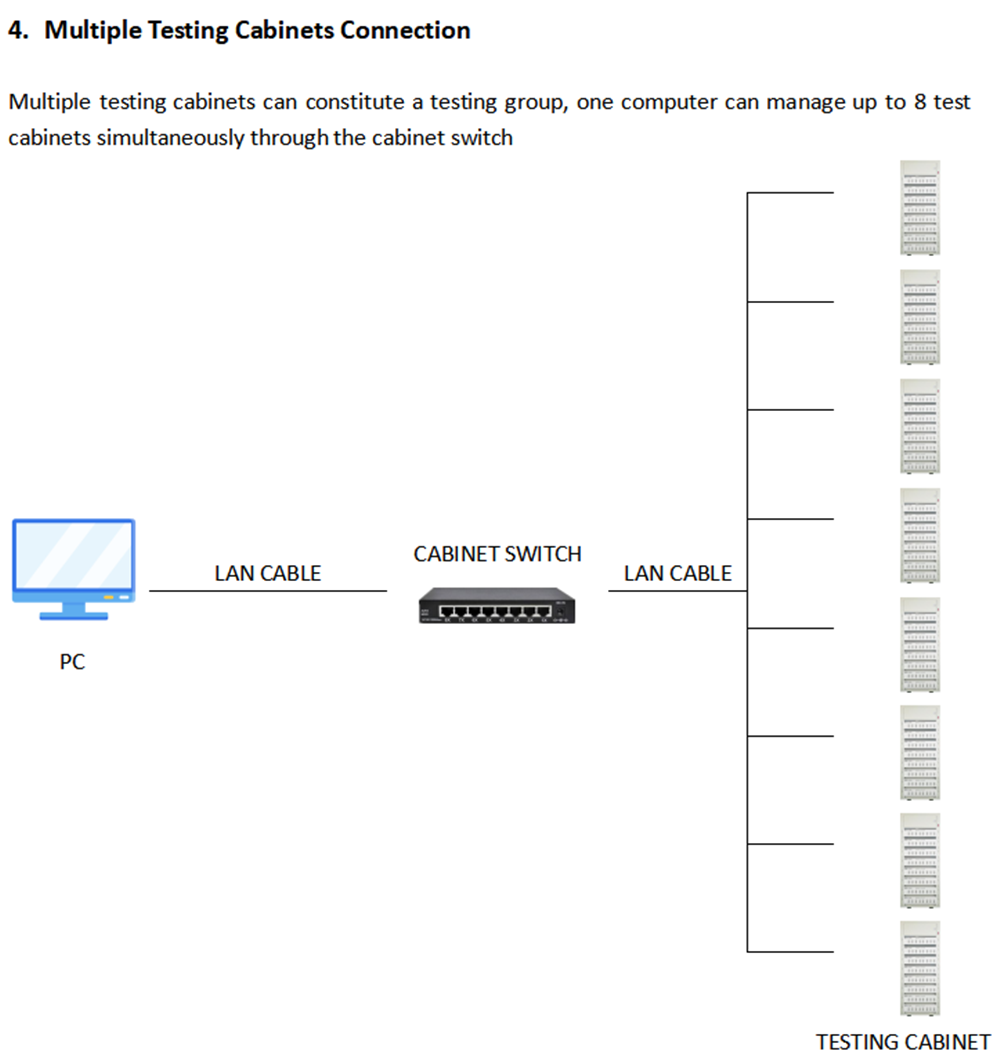

Device Connection Diagram:

Product Advantages

Cost-Effective Testing Solution:The 5V 10A Li-ion Tester DT50W-20 offers exceptional value for manufacturers and businesses looking to enhance their testing capabilities without breaking the bank. Its reliability ensures that you can perform accurate tests consistently.

Fast and Efficient:Designed for speed, the DT50W-20 enables quick battery testing, which increases your overall productivity and reduces downtime in the testing process.

Energy-Efficient Operation:This tester is optimized for low energy consumption, making it an environmentally friendly choice while helping your business save on electricity costs.

Compact and Portable:The compact design of the tester ensures easy portability, allowing businesses to carry it between various testing stations or to different sites with minimal hassle.

About Us

At DK-Tester, we specialize in providing advanced battery testing solutions, offering high-quality testers for a wide range of applications. With years of expertise in designing and manufacturing top-tier testing equipment, our mission is to empower manufacturers and businesses to ensure the quality and performance of their products. We provide reliable, user-friendly, and precise tools to measure, test, and analyze batteries in industries ranging from automotive to energy storage systems.

Why Choose Us

Industry Expertise:With years of experience in the battery testing industry, DK-Tester brings unmatched expertise to the table. We understand the needs of our customers and continually innovate to meet industry standards.

High-Quality Products:Our testers are crafted with precision and designed to meet the highest industry standards. We offer cutting-edge battery testing equipment that delivers accurate and consistent results.

Tailored Solutions:We provide customized testing equipment to meet the specific needs of different industries. Whether you're testing car batteries, energy storage solutions, or other types of batteries, we offer equipment to match your requirements.

Reliable Customer Support:Our dedicated customer support team is always ready to assist. Whether you need help with setup, troubleshooting, or after-sales service, we are committed to providing timely and professional support.

Global Reach:We serve customers worldwide, offering flexible solutions and shipping to ensure that our testers reach you, no matter your location. We are dedicated to building long-term relationships with clients across the globe.

FAQ

1. Who are we?

We are DK-Tester, a leading provider of advanced battery testing equipment. Our company specializes in designing and manufacturing high-quality testers for a range of industries, including automotive, energy storage, and electronics. With years of expertise, we deliver reliable, precise, and durable testing solutions that ensure the highest performance of your battery systems.

2. How can we guarantee quality?

We guarantee the highest quality by adhering to strict quality control procedures throughout the manufacturing process. Our products undergo rigorous testing and are built with the best materials to ensure long-lasting and accurate results. We also work with experienced engineers and industry professionals to continuously improve our products, ensuring they meet and exceed industry standards.

3. What can you buy from us?

Li-ion Cell Grading Testers

Car Battery Testers

Battery Checking Equipment for Energy Storage Systems

Industrial Battery Testers

Custom Battery Testing Solutions

4. Why should you buy from us and not from other suppliers?

We provide cutting-edge technology and precision testing tools that ensure the highest level of accuracy.

Our products are highly customizable to meet your specific needs.

We offer excellent customer service, providing technical support and guidance throughout your experience.

Our competitive pricing ensures that you get the best value for your investment.

We have a proven track record of delivering reliable and durable products worldwide.

5. What services can we provide?

Product Customization: Tailored solutions to fit your specific battery testing needs.

Technical Support: Assistance with installation, troubleshooting, and operational guidance.

After-Sales Service: Ongoing support to ensure the longevity and functionality of your equipment.

Consultation: Expert advice on choosing the right testing equipment for your business.

Worldwide Shipping: Fast and reliable delivery to customers around the world.