High-Precision EV Battery Testing for Industrial Applications

Designed for professionals, the EV Battery Testing DSF2010-40 offers unparalleled accuracy in testing battery capacity. Whether you are testing for automotive, industrial, or consumer electronics, this equipment provides precise data, essential for informed decision-making.

Why Choose DK's EV Battery Testing DSF2010-40?

At DK, we understand the importance of accuracy and reliability in battery testing. Our DSF2010-40 model is built with advanced technology, ensuring consistent performance and dependable results, making it the go-to choice for battery test equipment companies and wholesale suppliers.

Comprehensive Testing Capabilities

With a broad range of testing capabilities, the DSF2010-40 can handle multiple battery types, including lithium-ion, lead-acid, and more. This versatility makes it an essential tool for companies offering car battery testers and other related products.

Trusted by Industry Leaders

Join the ranks of industry leaders who trust DK for their battery testing needs. The DSF2010-40 is not just a product; it's a commitment to quality and precision in every test.

DSF2010-40 is suitable for capacity testing, charge and discharge characteristic testing, capacity grading and matching, balance charge and discharge maintenance, internal resistance testing of various batteries of Lead-acid, Lithium-ion, Polymer, Nickel-Metal Hydride, and Nickel-Chromium. DSF2010 isolation detection technology can determine the location of the defective modules without disassembling the battery pack, then replace it. It can balance charge and discharge the unbalanced battery pack to balance the battery and restore the battery pack to normal balance.

The device is integrated with Battery Temperature Monitoring System, work step switching and charging stop can be realized by setting the temperature to ensure accurate and safe battery testing & maintenance with unattended.

DSF2010-40 can perform one-time efficient and accurate testing and maintenance of battery packs within 40 modules or 40 strings at the same time. It is an ideal tool for testing and repairing batteries in electric vehicles and hybrid vehicles which is widely used for battery performance testing, maintenance, regeneration, pack assembling, pack rebuilding in automobile service industry.

DSF2010-40

Applicable Batteries:

Lead-acid/Li-Ion/polymer/Ni-MH/Ni-Cd Batteries, etc.

Features:

• Each channel is equipped with a dedicated processor to ensure a perfect level of capacity calculation, timing, voltage and current control.

• All channel is under isolated test, it can directly test the cells of the battery pack.

• Independent heat source channel, temperature control and speed regulation fan.

• The LED light indicates the running status, testing status, matching status, alarm status.

• Fully compatibility with the batteries of Lead-acid, Li-ion, Polymer, Ni-MH, NiCad, and so on.

• Online test between computer and device, the setting and result is particular and plentiful,

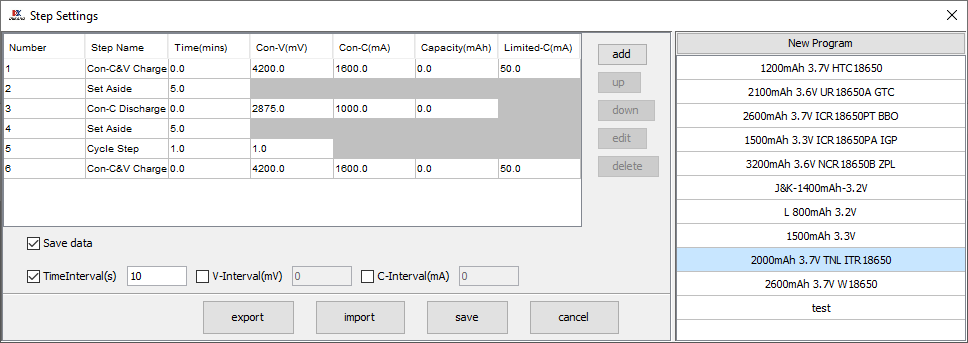

• With the work steps of Constant Current Discharge, Constant Power Discharge, Constant Resistance Discharge, Constant Current Charge, Constant Voltage Charge, Constant Current & Voltage Charge, Internal Resistance Test and Idle, etc.

• Work step automatically switching.

• The charge and discharge parameters can be customized.

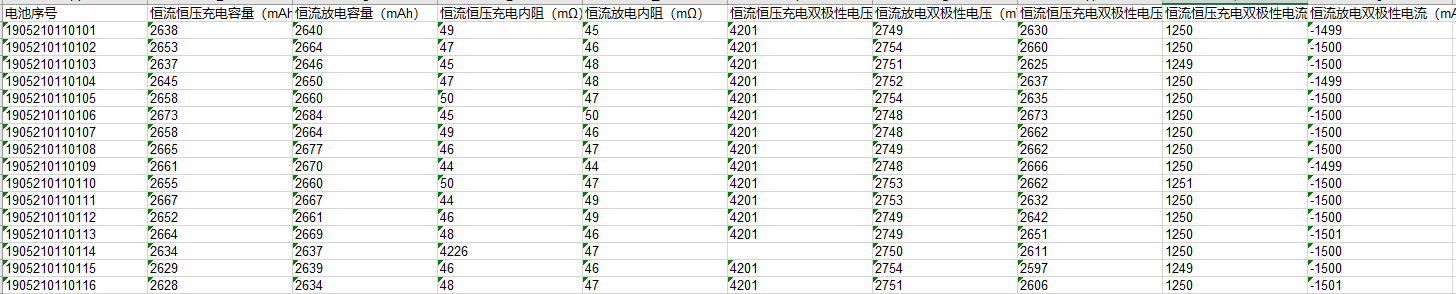

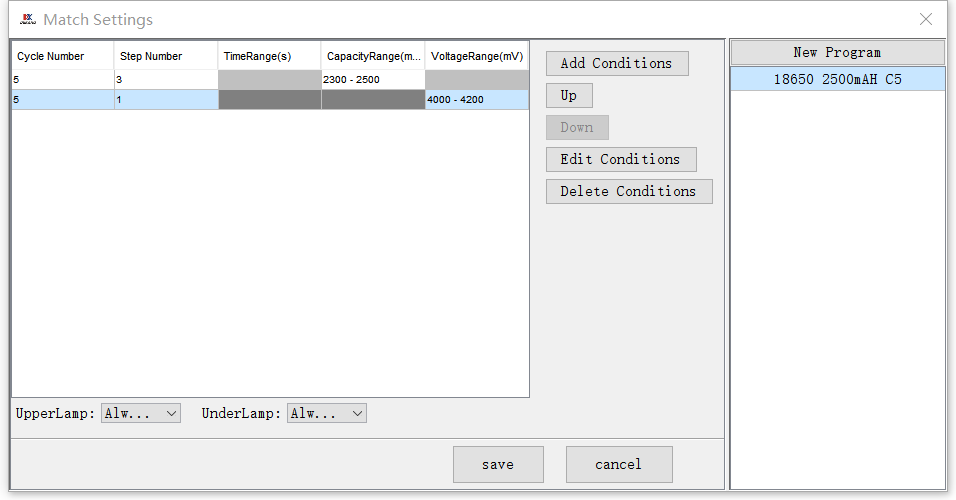

• The matching can be processed, the test results can be matched according to the customized standard, and it can mark and display on the device.

• Battery anti-reverse connection protection and alarm.

• The recording function of the test process.

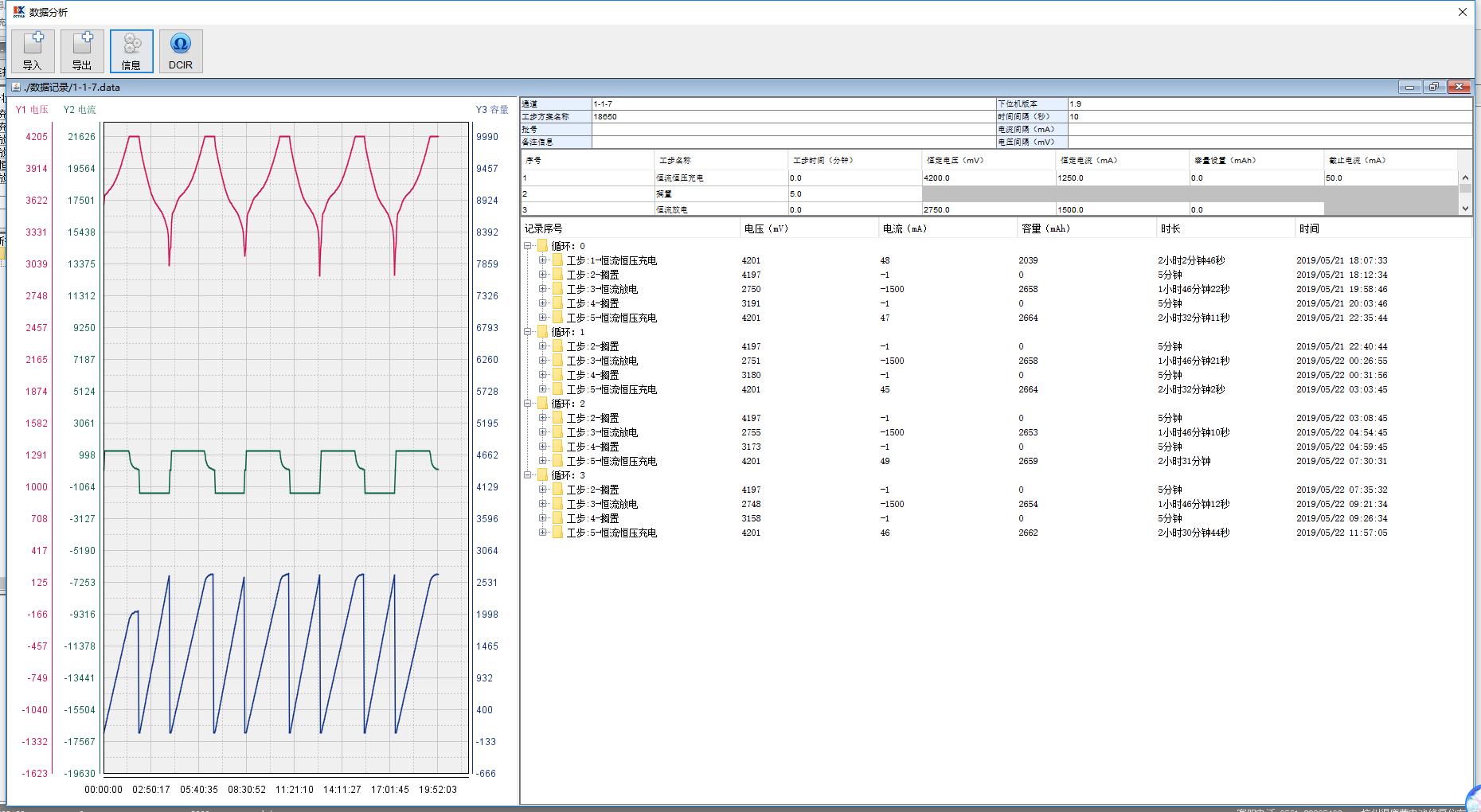

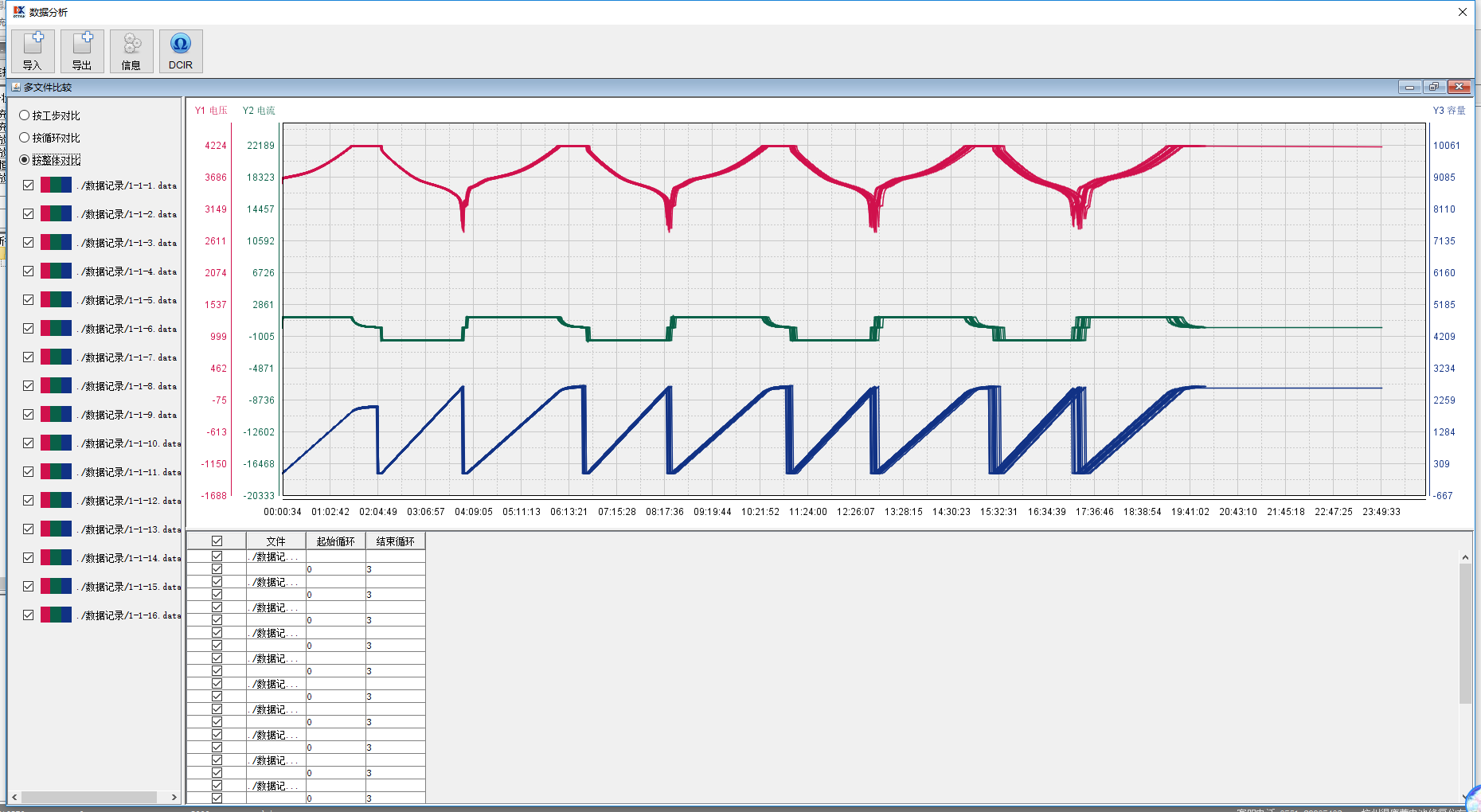

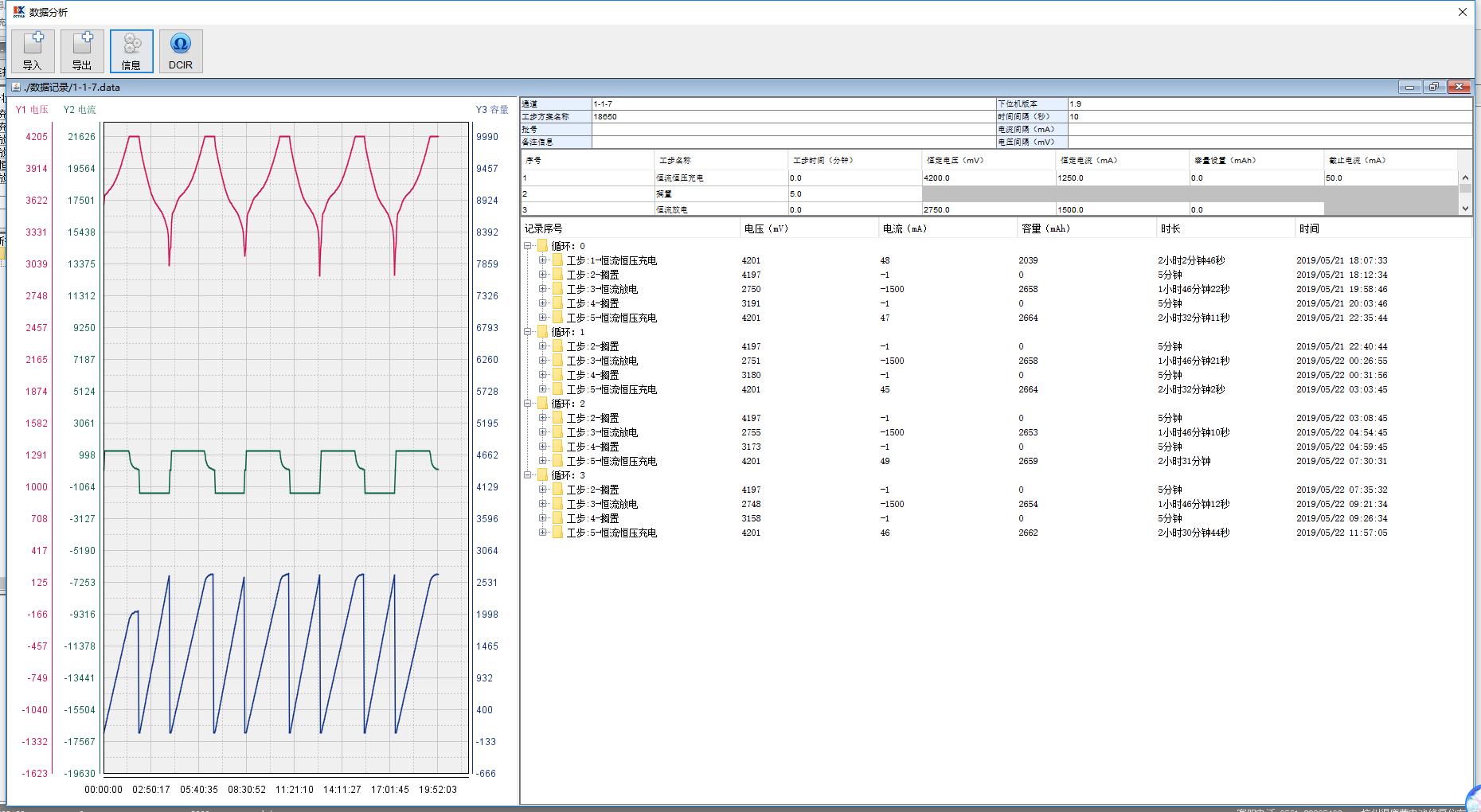

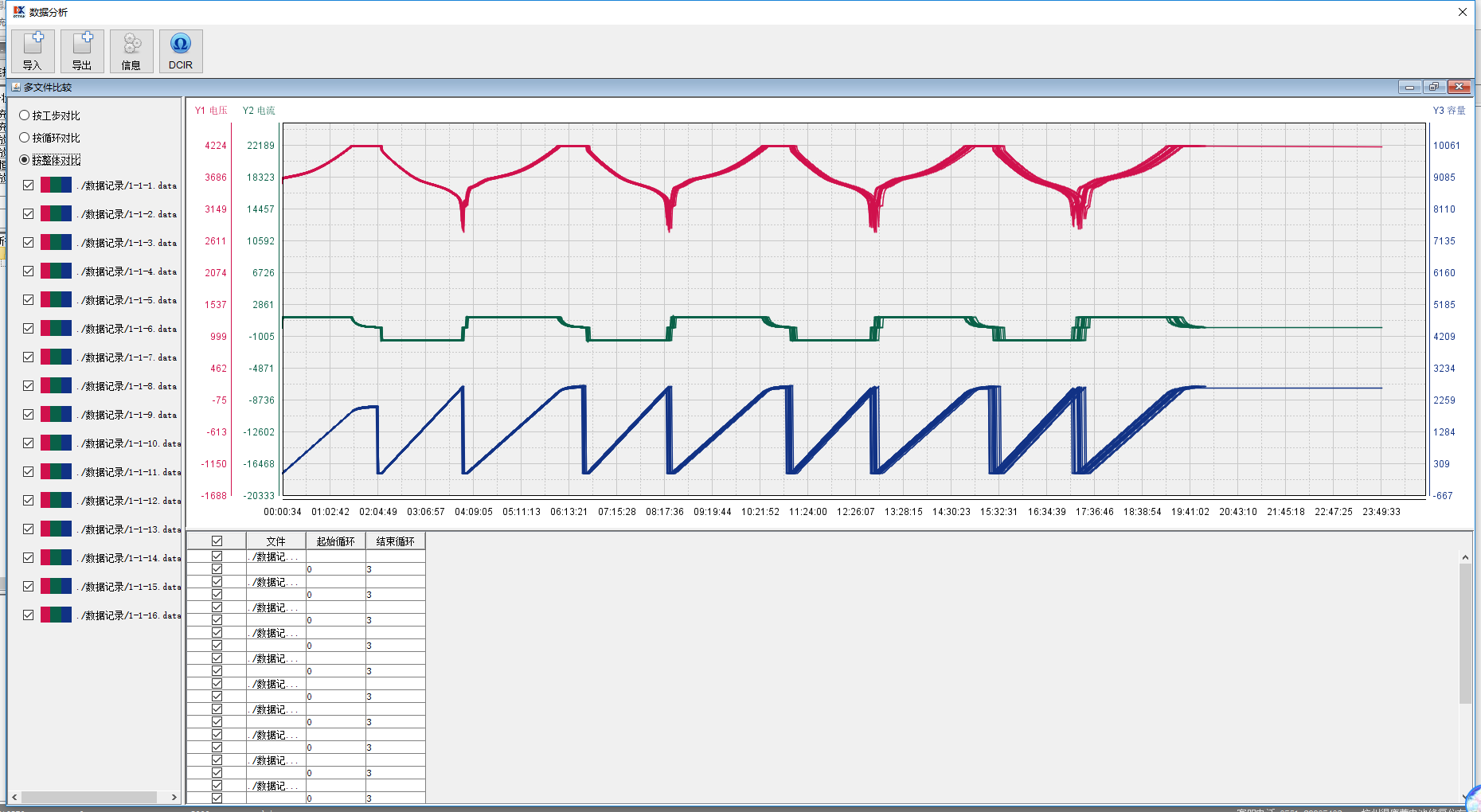

• With 3 Y-axis (voltage, current, capacity) and a time axis curve drawing ability, and data report function.

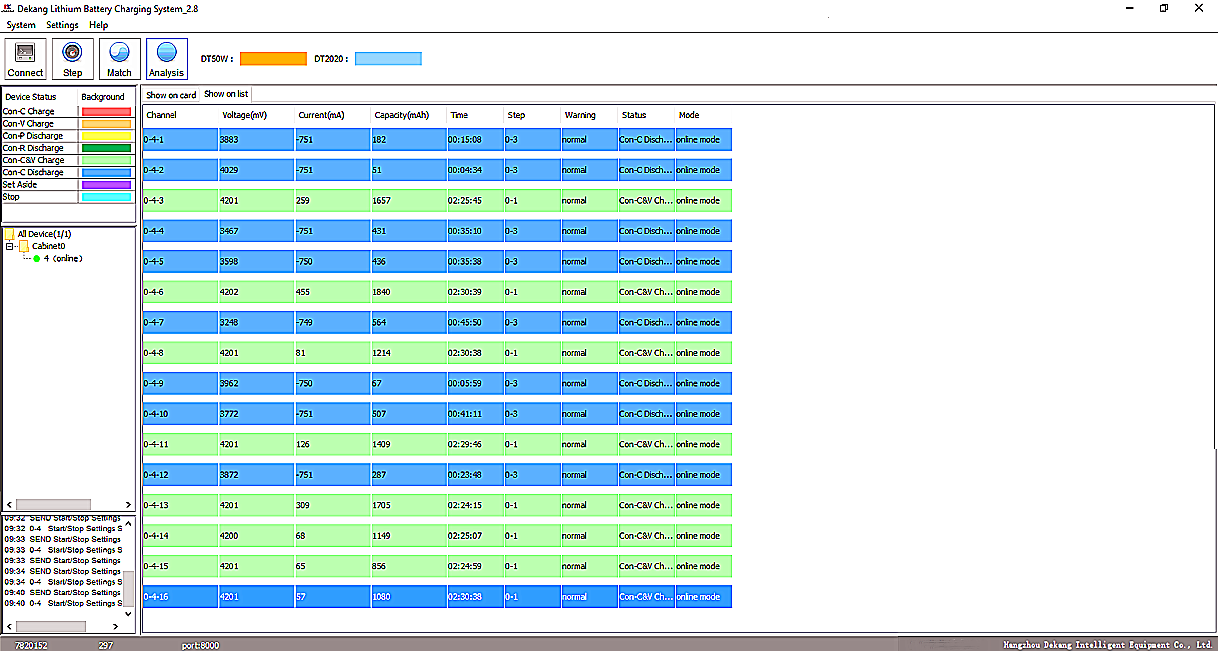

• The color of the test status bar is customized, which makes it easy to check the test status of all devices when the number of tests is large.

• Isolation channel battery temperature monitoring system, work step switching and charging stop can be realized by setting the temperature to ensure accurate and safe battery testing & maintenance with unattended.

Application Cases:

TechnicalSpecification:

| Model No.: DTSF2010-40 |

| Input Voltage: |

AC 220V± 10% 50Hz/60Hz |

| Input Power: |

No-load 100W, full load 1920W |

Voltage

|

Charge Constant Voltage Range: |

1 V – 20 V adjustable |

| Discharge Cut-off Voltage Range: |

1 V – 20 V adjustable |

| Tolerance: |

± 0.02 V |

Current

|

Charge Current: |

0.05 A – 10 A Adjustable |

| Discharge Current: |

0.05 A – 10 A Adjustable |

| Charge Cut-off Current: |

0.05A – 5 A |

| Tolerance: |

± 0.02 A |

| Power |

Max. Output Power (Single Channel) |

230 W |

Data Recording

|

Data Recording Conditions

|

Time interval |

| Voltage interval |

| Current interval |

Charge

|

Charge Modes:

|

Constant current charge |

| Constant voltage charge |

| Constant current & voltage charge |

| Charge Cut-off Conditions: |

Voltage, Current, Time, Capacity, -△V. Temperature |

Discharge

|

Discharge Modes:

|

Constant current discharge |

| Constant power discharge |

| Constant resistance discharge |

| Discharge Cut-off Conditions: |

Voltage, current, time, capacity |

| Cycle |

Cycle Index: |

1-999times |

Protection

|

Power-down protection |

| Reverse connection |

| Over-temperature protection |

| Over-voltage protection |

| Short-circuit protection |

| IP Grade |

IP20 |

| Channel Control Mode |

Independent control |

| High Voltage Insulation Between Channels |

AC1000V/2min Normal |

| Voltage & Current Test Sampling |

Four-core wires connection |

| Noise |

< 76 dB |

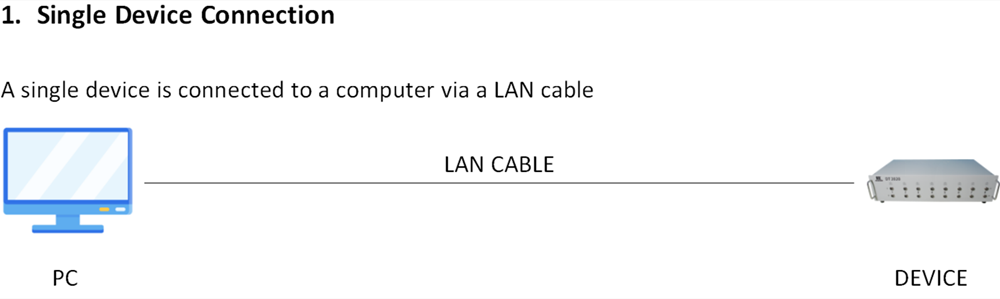

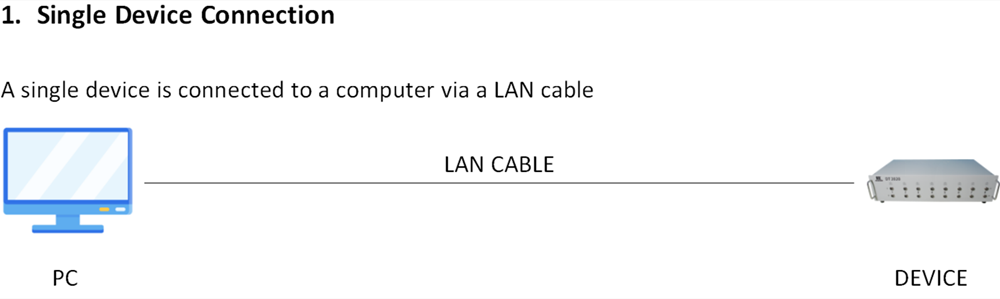

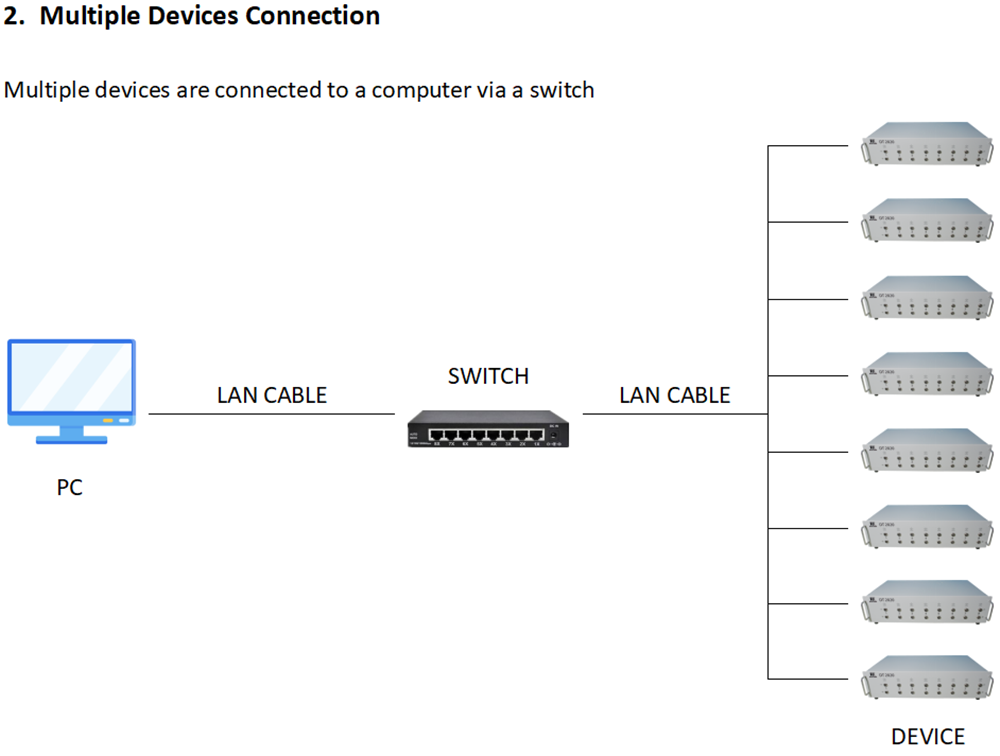

| Host Computer Communication Method |

based on TCP/IP protocol |

| Test Report Output Method |

Excel |

| Server Disk Configuration |

>100GB |

| Server Operation System |

Windows XP, Windows 7/8/10 |

| Communication Port |

LAN |

| |

|

| Equipment Work Ambient Conditions |

| Operation Ambient Temperature |

0 ℃ - 40 ℃ |

| Storage Temperature |

-10 ℃ - 50 ℃ |

| Operation Ambient Humidity |

≤ 70 % RH (No condensation) |

| Storage Ambient Humidity |

≤ 80 % RH (No condensation) |

Illustrations:

Produce Size: 80*50*146 cm(L*W*H)

Weight:: 185 kgs

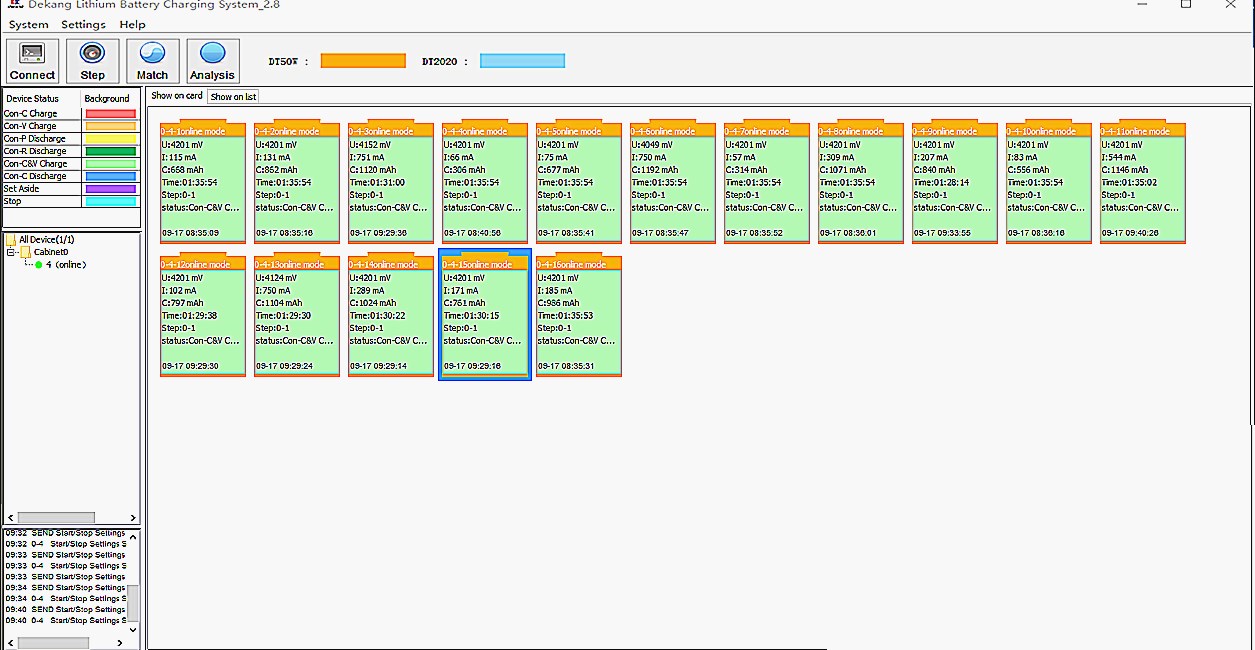

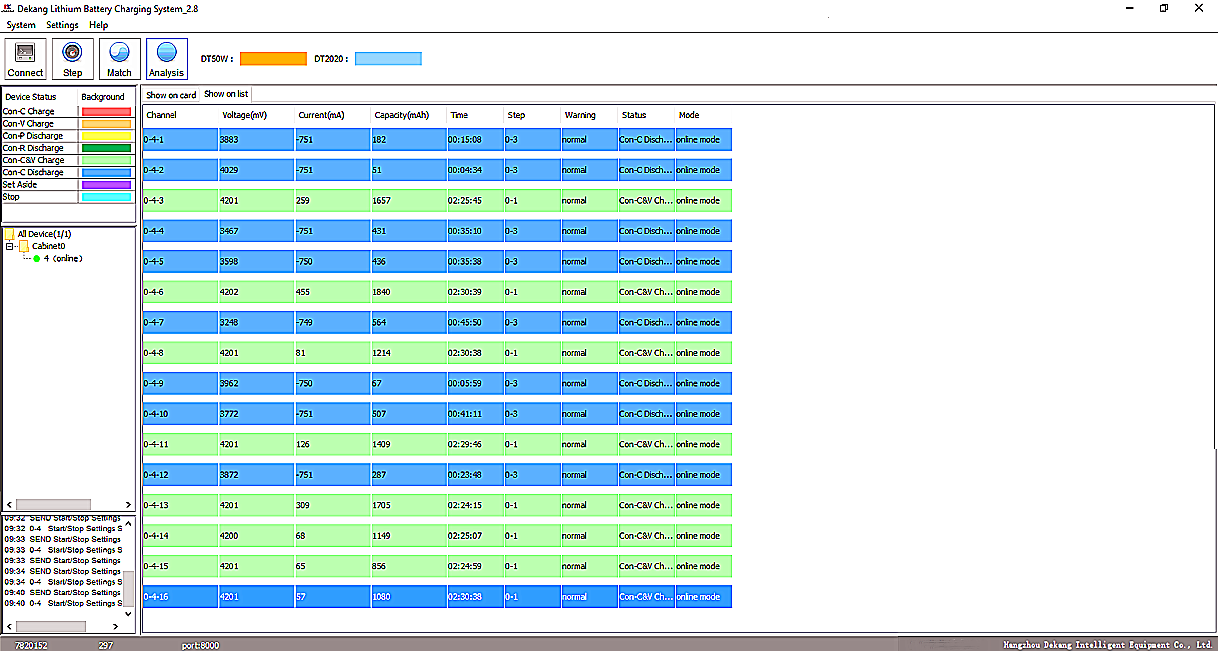

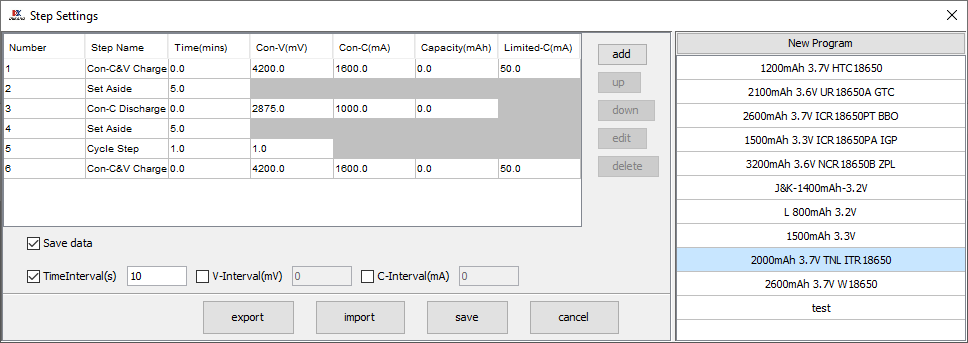

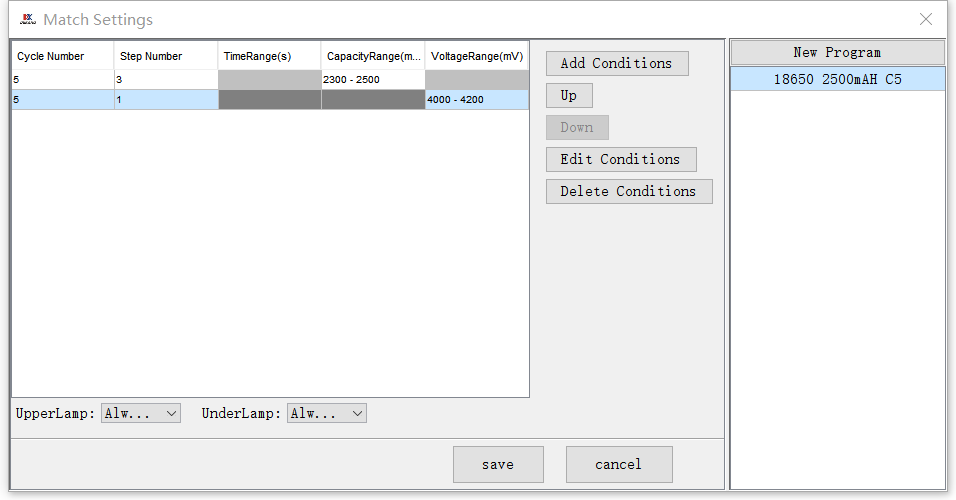

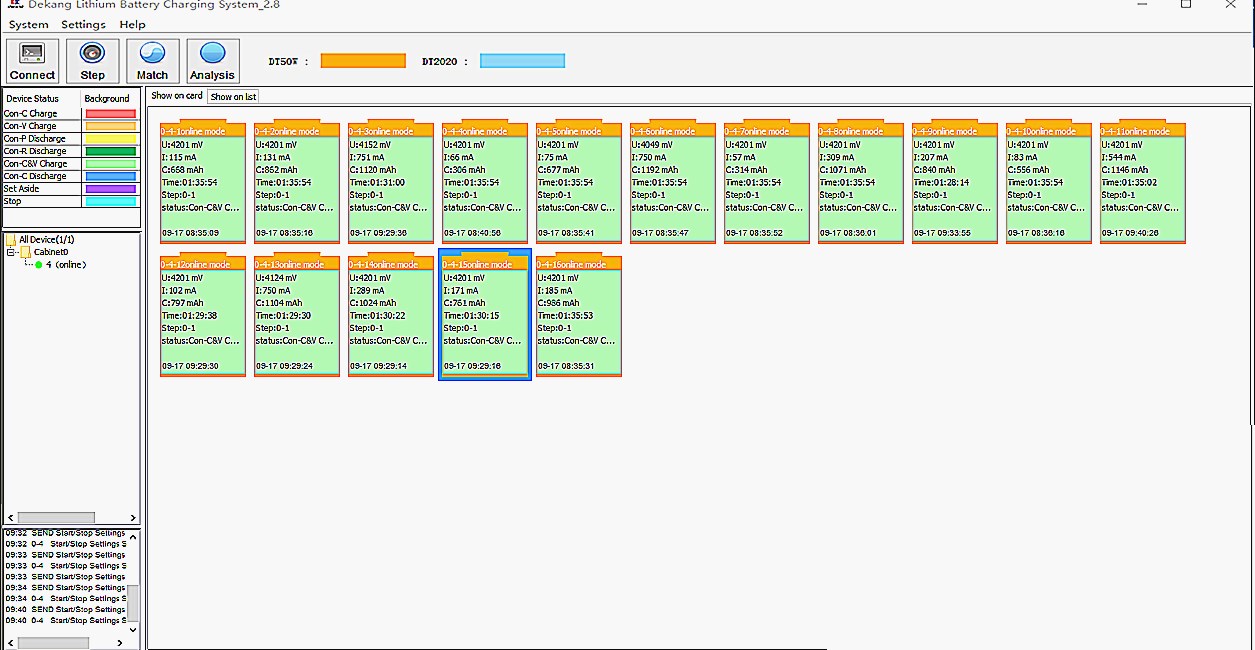

Software Interfaces

Main Interfaces

List Display

Work Step Setting

Match Conditions Setting

Single Channel Data Analysis

Multiple Channel Data Analysis and Comparison

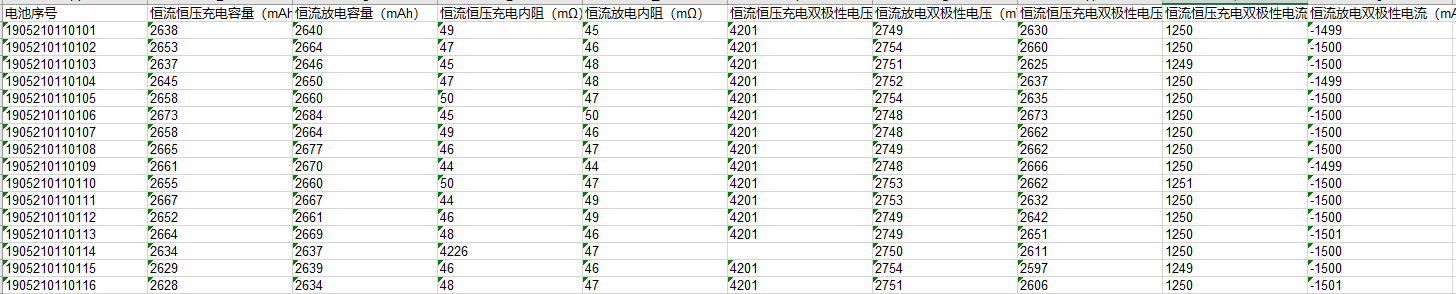

Test Data Exporting

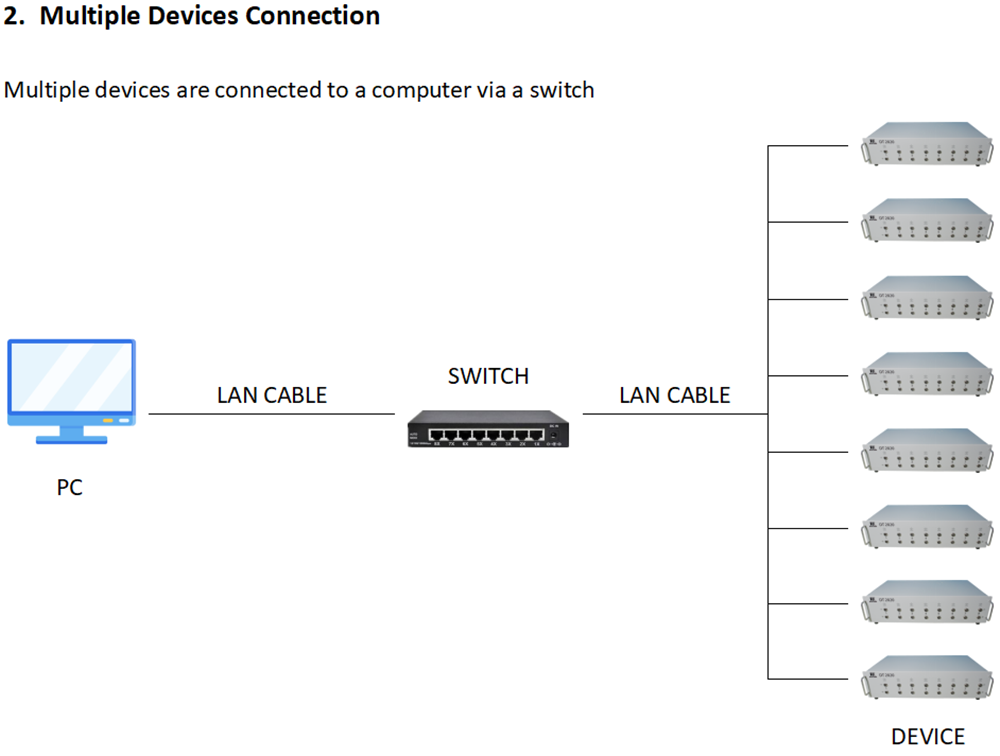

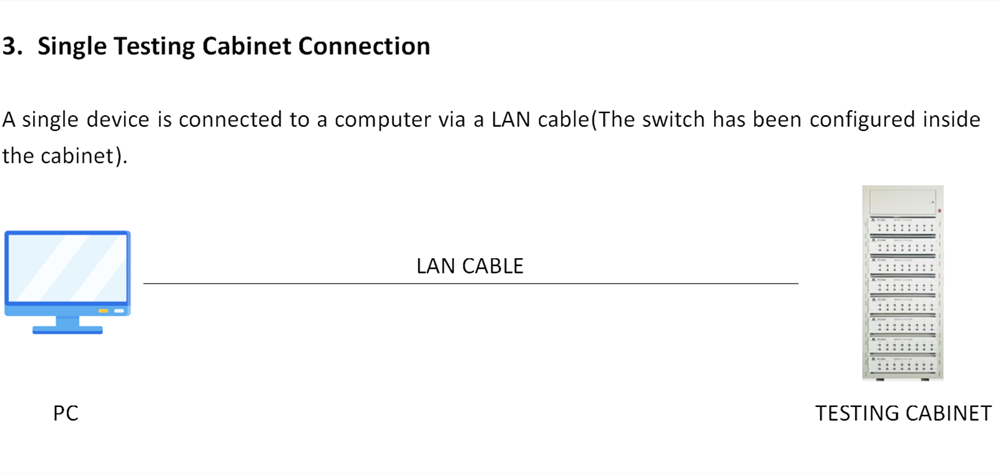

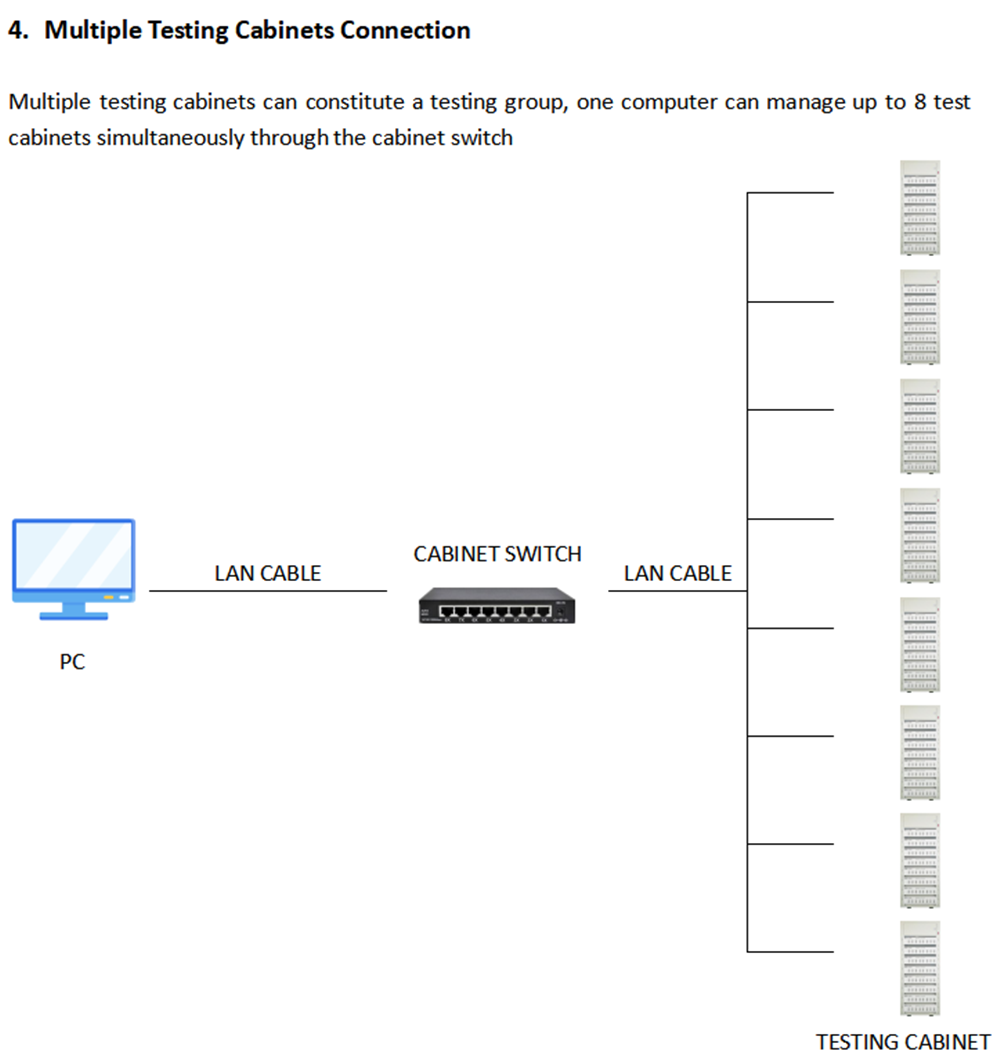

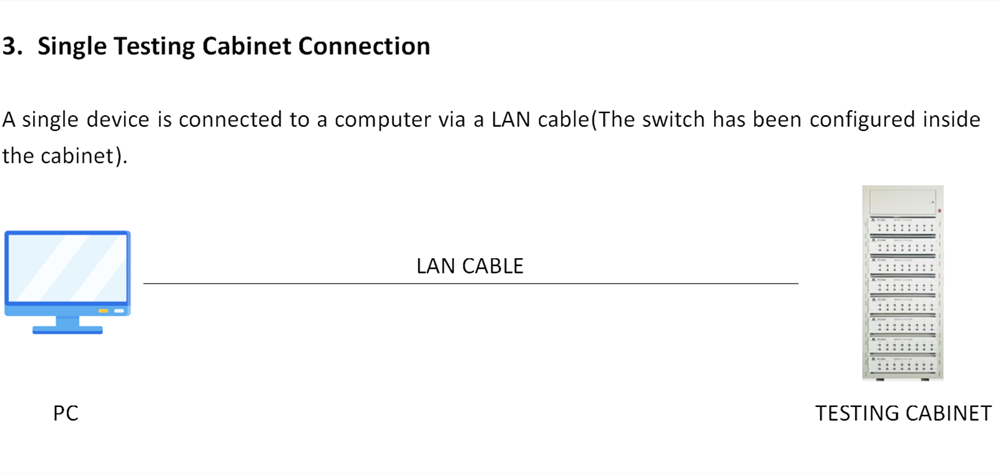

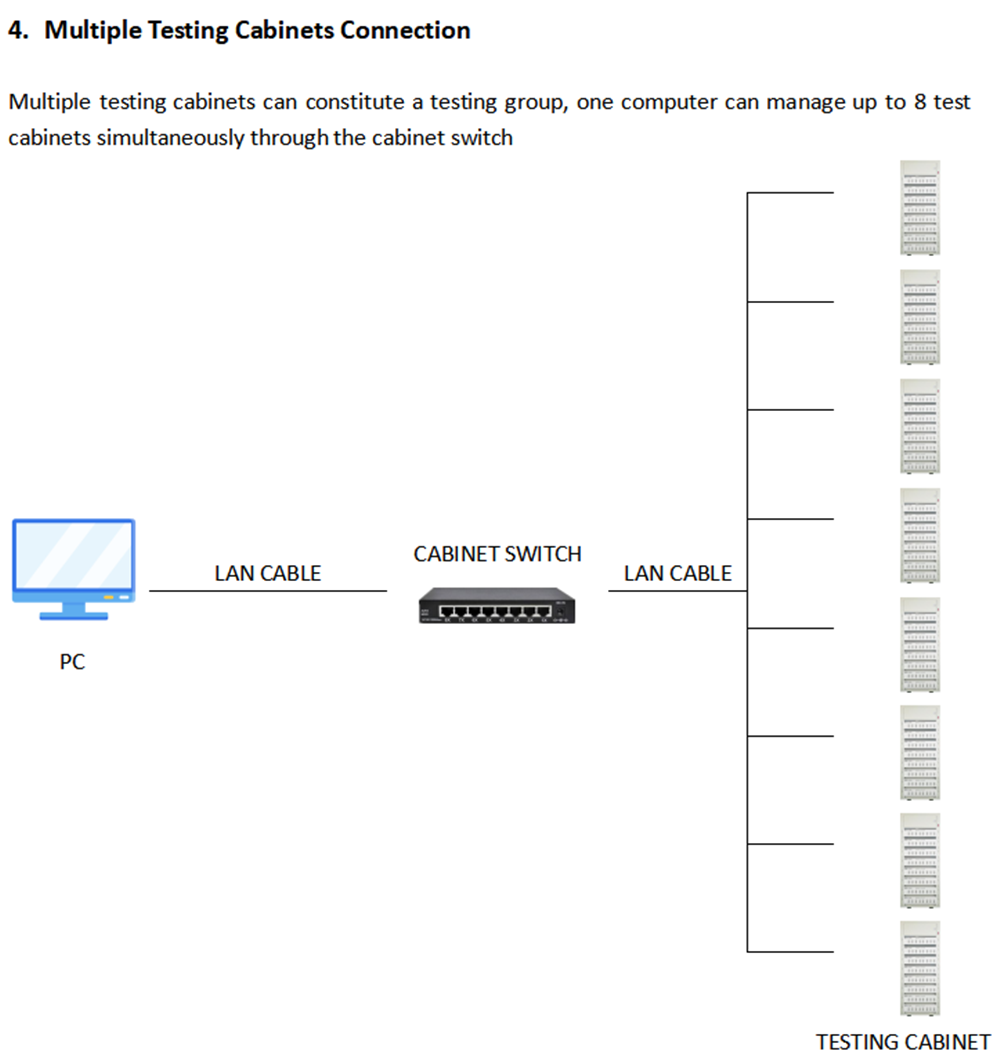

Device Connection Diagram:

Product Advantages

High Accuracy and Precision:The DSF2010-40 ensures accurate testing, offering highly reliable data for evaluating the performance of EV batteries. This is crucial for manufacturers focused on quality control and performance optimization.

Improved Battery Life:By identifying potential issues early in the testing phase, manufacturers can make necessary adjustments, thereby enhancing the longevity and efficiency of EV batteries.

User-Friendly Interface:Equipped with an intuitive interface, the system simplifies the testing process, reducing the need for extensive operator training while maintaining high testing standards.

Cost-Efficiency:The DSF2010-40 helps reduce operational costs by automating many testing processes, thus minimizing the time and labor involved in manual testing.

About Us

At DK-Tester, we specialize in providing advanced battery testing solutions, offering high-quality testers for a wide range of applications. With years of expertise in designing and manufacturing top-tier testing equipment, our mission is to empower manufacturers and businesses to ensure the quality and performance of their products. We provide reliable, user-friendly, and precise tools to measure, test, and analyze batteries in industries ranging from automotive to energy storage systems.

FAQ

1. Who are we?

We are DK-Tester, a leading provider of advanced battery testing equipment. Our company specializes in designing and manufacturing high-quality testers for a range of industries, including automotive, energy storage, and electronics. With years of expertise, we deliver reliable, precise, and durable testing solutions that ensure the highest performance of your battery systems.

2. How can we guarantee quality?

We guarantee the highest quality by adhering to strict quality control procedures throughout the manufacturing process. Our products undergo rigorous testing and are built with the best materials to ensure long-lasting and accurate results. We also work with experienced engineers and industry professionals to continuously improve our products, ensuring they meet and exceed industry standards.

3. What can you buy from us?

Li-ion Cell Grading Testers

Car Battery Testers

Battery Checking Equipment for Energy Storage Systems

Industrial Battery Testers

Custom Battery Testing Solutions

4. Why should you buy from us and not from other suppliers?

We provide cutting-edge technology and precision testing tools that ensure the highest level of accuracy.

Our products are highly customizable to meet your specific needs.

We offer excellent customer service, providing technical support and guidance throughout your experience.

Our competitive pricing ensures that you get the best value for your investment.

We have a proven track record of delivering reliable and durable products worldwide.

5. What services can we provide?

We offer a wide range of services, including:

Product Customization: Tailored solutions to fit your specific battery testing needs.

Technical Support: Assistance with installation, troubleshooting, and operational guidance.

After-Sales Service: Ongoing support to ensure the longevity and functionality of your equipment.

Consultation: Expert advice on choosing the right testing equipment for your business.

Worldwide Shipping: Fast and reliable delivery to customers around the world.