By Emily Q. Harris | 08 October 2024 | 0 Comments

Crafting a Greener Future with Sustainable Recycling of Battery Testing Equipment

In an era where eco-friendliness and sustainability are more than just buzzwords, the proper recycling and disposal of battery testing equipment have become pivotal. For environmentalists, battery industry professionals, and sustainability advocates, it’s clear that the way we handle e-waste impacts our planet significantly. This article explores sustainable practices that are crucial for recycling and disposing of battery testing equipment, aiming to inspire change and innovation across industries.

Table of contents

Simplifying Disassembly for Better Recycling

Establishing Robust Recycling Programs and Partnerships

The Role of Recyclable Materials in Sustainable Design

Navigating Environmental Regulations for Safe Disposal

Elevating Brand Credibility with Environmental Certifications

For battery testing equipment suppliers, integrating such design principles can be a game-changer. It not only aligns with environmental goals but also boosts the appeal of their products to a more environmentally conscious market. Modularity allows for easier repair and refurbishment, extending the lifespan of equipment and minimizing the ecological footprint of new production.

Strategic partnerships with recycling experts help ensure that every aspect of the disposal process is handled with care. Such collaborations not only guarantee compliance with environmental regulations but also enhance a company's commitment to sustainability. By aligning with reputable recyclers, battery testing equipment suppliers can assure customers that their products’ end-of-life phase is managed conscientiously.

Advancements in technology are driving the shift towards fully recyclable components, making it a feasible and necessary goal. By choosing materials that align with sustainability criteria, manufacturers can create equipment that not only performs well but also respects the planet.

By committing to regulatory compliance, companies reassure consumers that their products are managed sustainably throughout their lifecycle. This dedication not only builds trust but also prevents potential legal issues stemming from improper disposal practices.

As awareness grows, the demand for certified sustainable products is set to increase, making it a strategic advantage for companies. For battery testing equipment suppliers, securing such certifications can open new markets and attract environmentally conscious buyers.

The recycling and disposal of battery testing equipment present complex challenges that demand coordinated efforts across design, manufacturing, and consumer engagement. By focusing on ease of disassembly, establishing recycling programs, utilizing recyclable materials, ensuring regulatory compliance, and obtaining environmental certifications, companies can significantly reduce the environmental impact of their products. As we progress toward a more sustainable future, adopting these practices is not just beneficial but essential for both the planet and industry innovation. For those interested in exploring more sustainable practices, further resources can be found at https://dk-tester.com/.

Table of contents

Simplifying Disassembly for Better Recycling

Establishing Robust Recycling Programs and Partnerships

The Role of Recyclable Materials in Sustainable Design

Navigating Environmental Regulations for Safe Disposal

Elevating Brand Credibility with Environmental Certifications

Simplifying Disassembly for Better Recycling

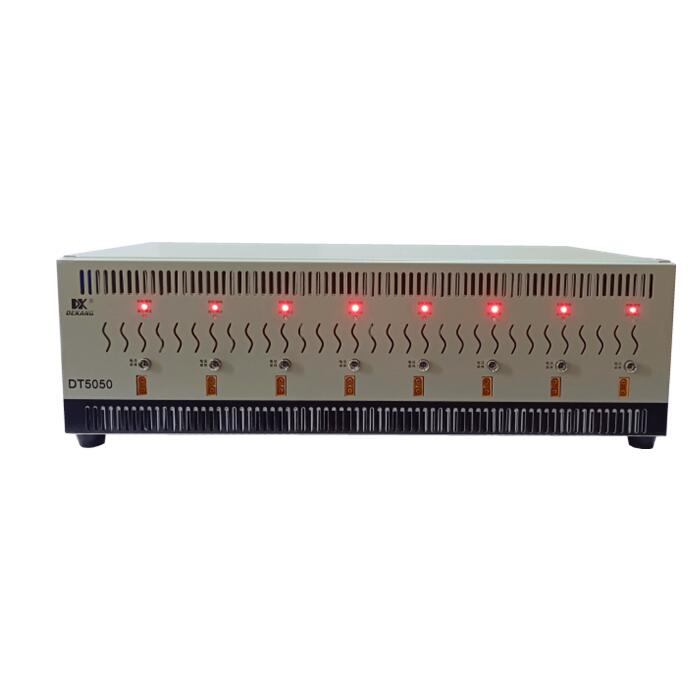

One of the primary challenges in recycling battery testing equipment is ensuring that the devices are easy to disassemble. Modern designs are focusing on modularity, allowing parts to be separated without requiring specialized tools. This approach not only facilitates recycling but also promotes repurposing of components, effectively reducing waste. Manufacturers are increasingly adopting these eco-friendly designs, which makes it easier for end-users to participate in the recycling process. By prioritizing ease of disassembly, companies can significantly enhance their recycling efficiency.For battery testing equipment suppliers, integrating such design principles can be a game-changer. It not only aligns with environmental goals but also boosts the appeal of their products to a more environmentally conscious market. Modularity allows for easier repair and refurbishment, extending the lifespan of equipment and minimizing the ecological footprint of new production.

Establishing Robust Recycling Programs and Partnerships

The success of recycling initiatives often hinges on the availability of robust programs and partnerships with third-party recyclers. Companies that offer take-back schemes add tremendous value by simplifying the disposal process for consumers. These programs guide users in responsible equipment disposal, ensuring materials are recycled in an environmentally safe manner.Strategic partnerships with recycling experts help ensure that every aspect of the disposal process is handled with care. Such collaborations not only guarantee compliance with environmental regulations but also enhance a company's commitment to sustainability. By aligning with reputable recyclers, battery testing equipment suppliers can assure customers that their products’ end-of-life phase is managed conscientiously.

The Role of Recyclable Materials in Sustainable Design

Integrating recyclable materials into the construction of battery testing equipment is essential for minimizing environmental impact. The use of materials that are easy to repurpose reduces landfill contributions and saves natural resources. This practice supports sustainability while enhancing the market appeal of equipment by meeting consumer demand for eco-friendly products.Advancements in technology are driving the shift towards fully recyclable components, making it a feasible and necessary goal. By choosing materials that align with sustainability criteria, manufacturers can create equipment that not only performs well but also respects the planet.

Navigating Environmental Regulations for Safe Disposal

Compliance with environmental regulations is a critical aspect of disposing of battery testing equipment. Adhering to local and international guidelines ensures that the disposal process does not negatively impact the environment. Manufacturers must stay informed about evolving regulations to maintain compliance, thereby protecting both the environment and their brand integrity.By committing to regulatory compliance, companies reassure consumers that their products are managed sustainably throughout their lifecycle. This dedication not only builds trust but also prevents potential legal issues stemming from improper disposal practices.

Elevating Brand Credibility with Environmental Certifications

Achieving environmental certifications can significantly enhance a company's reputation. Certifications from recognized bodies confirm that the equipment meets high standards for recyclability and sustainable disposal. These credentials validate a manufacturer's dedication to the environment, giving consumers confidence in their choices.As awareness grows, the demand for certified sustainable products is set to increase, making it a strategic advantage for companies. For battery testing equipment suppliers, securing such certifications can open new markets and attract environmentally conscious buyers.

The recycling and disposal of battery testing equipment present complex challenges that demand coordinated efforts across design, manufacturing, and consumer engagement. By focusing on ease of disassembly, establishing recycling programs, utilizing recyclable materials, ensuring regulatory compliance, and obtaining environmental certifications, companies can significantly reduce the environmental impact of their products. As we progress toward a more sustainable future, adopting these practices is not just beneficial but essential for both the planet and industry innovation. For those interested in exploring more sustainable practices, further resources can be found at https://dk-tester.com/.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Boosting Energy Efficiency in Battery Testing: Strategies for Sustainable Operations

- Top 5 Car Battery Testers of 2024: Unleash Peak Performance

- Advanced Battery Testing: Key to Efficient EV Manufacturing and Market Success

- Empowering Industries: Applications of Li-ion Battery Testing Equipment

- Maximize Your Electric Car's Performance with Our Battery Tester

CATEGORIES